Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Walk-in coolers are essential for businesses that require proper refrigeration, from restaurants to florists. However, they often face common issues that can disrupt operations and lead to costly downtime. Understanding these challenges is crucial for maintaining a functional compressor for walk-in cooler systems, which plays a vital role in keeping temperatures stable and products fresh.

Common Issues with Walk In Coolers

Walk-in coolers can suffer from various problems, including inconsistent temperatures, unusual noises, and even complete system failures. One of the most frequent culprits behind these issues is the walk-in cooler compressor and evaporator not functioning correctly. Identifying these common issues early on can help prevent more significant repairs or a complete walk-in cooler compressor replacement down the line.

Importance of a Functional Compressor

The compressor for walk-in cooler units is the heart of the refrigeration system; it circulates refrigerant through the system to maintain optimal temperatures. Without a functioning compressor, your commercial freezer compressor may struggle to keep up with demands, leading to spoilage and waste. Regular maintenance of your walk-in cooler refrigeration unit ensures that your business runs smoothly while minimizing the risk of unexpected breakdowns.

Overview of Troubleshooting Steps

Troubleshooting issues with your commercial walk-in freezer compressor involves several key steps that can help pinpoint problems effectively. Start by checking power supply issues and examining temperature controls before inspecting condenser coils for obstructions. By following these initial diagnostics, you can determine whether you need a simple fix or if it’s time to consider walk-in cooler compressor replacement costs or even consult a professional technician.

Understanding Your Compressor for Walk In Cooler

When it comes to the functionality of a walk-in cooler, understanding the compressor is crucial. The compressor serves as the heart of the refrigeration system, ensuring that your products stay at optimal temperatures. A well-functioning compressor for walk in cooler applications not only maintains quality but also enhances energy efficiency.

How Compressors Operate

Compressors are responsible for circulating refrigerant throughout the cooling system, converting low-pressure gas into high-pressure gas to facilitate heat exchange. In a typical walk-in cooler refrigeration unit, this cycle begins when the compressor draws in refrigerant vapor from the evaporator coil. The vapor is then compressed and sent to the condenser coils, where it releases heat and transforms back into a liquid state, ready to absorb more heat from inside your cooler.

Understanding this cycle is vital if you're considering a commercial freezer compressor or planning a walk-in cooler compressor replacement. Each step in this process contributes to maintaining consistent temperatures essential for food safety and product longevity. If any part of this cycle fails, you may face significant temperature fluctuations that can compromise your inventory.

Signs of a Failing Compressor

Recognizing early warning signs of a failing compressor can save you time and money on potential repairs or even a complete walk-in cooler compressor replacement. Common indicators include unusual noises such as grinding or hissing sounds, which may suggest mechanical failure or refrigerant leaks within your commercial walk-in freezer compressor system. Additionally, if you notice inconsistent temperatures or frequent cycling on and off, it's time to investigate further.

Another sign could be increased energy bills; an inefficient cooler compressor unit often works harder than necessary to maintain set temperatures, leading to higher operational costs. If you encounter any of these symptoms consistently, don’t wait too long before seeking assistance; ignoring them could lead to costly repairs down the line or even necessitate complete replacement due to extensive damage.

Importance of Regular Maintenance

Regular maintenance is essential for maximizing the lifespan and efficiency of your walk-in cooler refrigeration unit. By routinely checking components like filters and condenser coils, you can prevent issues that might lead to costly repairs or premature failures in your commercial freezer compressor system. Scheduled maintenance also helps ensure that all parts are functioning optimally—keeping energy costs low while maintaining ideal storage conditions.

Moreover, understanding how maintenance impacts performance can prevent unexpected downtime during peak business hours when your products need cooling most urgently. Investing in regular check-ups not only extends the life of your equipment but also enhances overall operational efficiency—making it an essential practice for any business relying on effective refrigeration solutions.

Initial Diagnostics for Compressor Problems

When dealing with a malfunctioning compressor for walk in cooler systems, the first step is to conduct initial diagnostics. These preliminary checks can uncover common issues that may be affecting the performance of your walk-in cooler refrigeration unit. By systematically addressing these areas, you can often identify the root cause of the problem before it escalates into a costly repair.

Checking Power Supply Issues

The power supply is the lifeblood of any compressor for walk in cooler systems, and if there are disruptions in this area, your entire cooling operation could be compromised. Start by ensuring that the electrical connections are secure and that there are no blown fuses or tripped circuit breakers. If everything appears normal but the compressor still isn’t running, consider testing the voltage with a multimeter to ensure it meets the required specifications for your commercial freezer compressor.

A common issue related to power supply is inadequate voltage reaching your walk-in cooler compressor and evaporator. If you discover low voltage levels, it could lead to overheating and eventual failure of your cooling unit. Addressing these electrical concerns promptly can save you from more extensive repairs or even a complete walk-in cooler compressor replacement down the line.

Examining Temperature Controls

Temperature controls play a crucial role in regulating how effectively your commercial walk in freezer compressor operates. Begin by checking if the thermostat settings are correct; sometimes they can be accidentally adjusted or malfunction altogether. If temperature readings are inconsistent or out of range, recalibrating or replacing faulty controls may be necessary to restore optimal functionality.

Another important aspect is ensuring that any sensors connected to your refrigeration unit are clean and functioning properly; dirty or damaged sensors can misread temperatures and lead to improper cooling cycles. This not only affects product quality but can also place undue stress on your system, leading to potential failures in both compressors and evaporators if left unchecked. Regular checks on temperature controls will help maintain efficiency and prolong the lifespan of your equipment.

Inspecting Condenser Coils for Obstructions

Condenser coils are vital components in any cooler compressor unit as they release heat absorbed from inside the refrigerator into the outside air. Over time, these coils can become clogged with dust, dirt, or other debris which impairs their efficiency significantly—leading to increased energy consumption and potential breakdowns of both commercial freezer compressors and walk-in cooler refrigeration units alike. Therefore, inspecting condenser coils regularly should be part of any maintenance routine.

To clean these coils effectively, turn off power to your system before using a brush or vacuum cleaner designed for this purpose—this will help avoid damaging delicate components while ensuring optimal airflow is restored around them. Additionally, check for signs of corrosion or damage; neglected coils might require professional intervention sooner rather than later if you want to avoid costly repairs like a full walk-in cooler compressor replacement cost later down the road!

By addressing these initial diagnostics thoroughly—power supply issues, temperature controls adjustments, and condenser coil inspections—you'll set yourself up for success when troubleshooting problems with your commercial refrigeration equipment.

Common Compressor Issues and Solutions

Refrigerant Leak Detection

Refrigerant leaks are among the most common problems encountered with commercial walk-in freezer compressors. If you notice that your cooler isn’t maintaining the desired temperature, checking for refrigerant leaks should be your first step. Signs of a leak may include hissing sounds near the compressor unit or ice buildup on evaporator coils; catching these issues early can save you from costly walk-in cooler compressor replacement costs down the line.

To detect a refrigerant leak effectively, consider using electronic leak detectors or soap solutions to identify escaping gas from joints and fittings in your walk-in cooler refrigeration unit. If you find a leak, it’s essential to repair it promptly; otherwise, you risk damaging your entire cooling system and incurring further expenses related to a commercial freezer compressor replacement. Regular maintenance checks can help prevent such leaks by ensuring that all components are secure and functioning properly.

Evaluating the Expansion Valve

The expansion valve is another critical component in the cooling process of your cooler compressor unit; if it's not functioning correctly, it can lead to inadequate cooling performance. Symptoms of an underperforming expansion valve may include fluctuating temperatures inside your walk-in cooler or excessive frost buildup on evaporator coils. Addressing these signs early on can help avoid more severe issues with your walk-in cooler compressor.

To evaluate the expansion valve's condition effectively, start by inspecting its settings and functionality; ensure that it's allowing refrigerant flow at appropriate rates based on current cooling demands. If you suspect that the expansion valve is faulty but lack experience with repairs, consulting an HVAC technician could save you time and effort while ensuring proper diagnosis and solution implementation for your commercial walk-in freezer compressor system. Remember that timely intervention can enhance efficiency and prolong the lifespan of your refrigeration equipment.

Addressing Noise or Vibration Problems

Unusual noises or vibrations coming from your cooler compressor unit shouldn’t be ignored—they often indicate underlying problems that need immediate attention. Common sources of noise include loose components within the commercial freezer compressor or debris caught in fan blades affecting operation efficiency. Ignoring these signs could lead to more extensive damage requiring costly repairs or even complete walk-in cooler compressor replacement.

To address noise issues effectively, first check for loose screws or bolts around the unit; tightening them may alleviate some vibrations immediately. Additionally, inspect fan blades for any obstructions that could be causing unwanted noise during operation—removing debris can significantly improve performance levels within your refrigeration system as well as extend its lifespan overall! If noise persists despite these adjustments, consider contacting a professional technician who specializes in troubleshooting commercial refrigeration systems.

The Role of the Arctic Active Cooling Unit

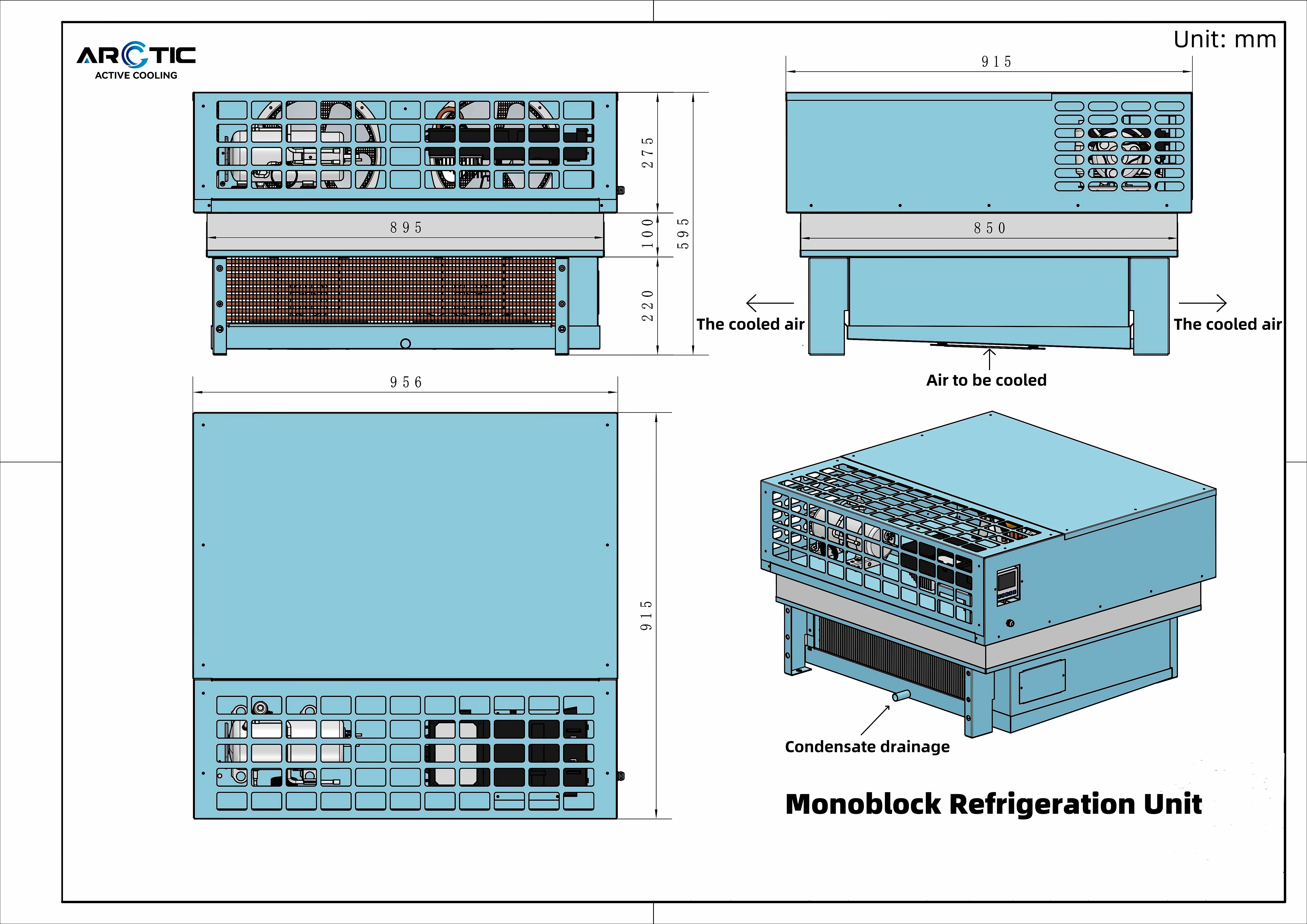

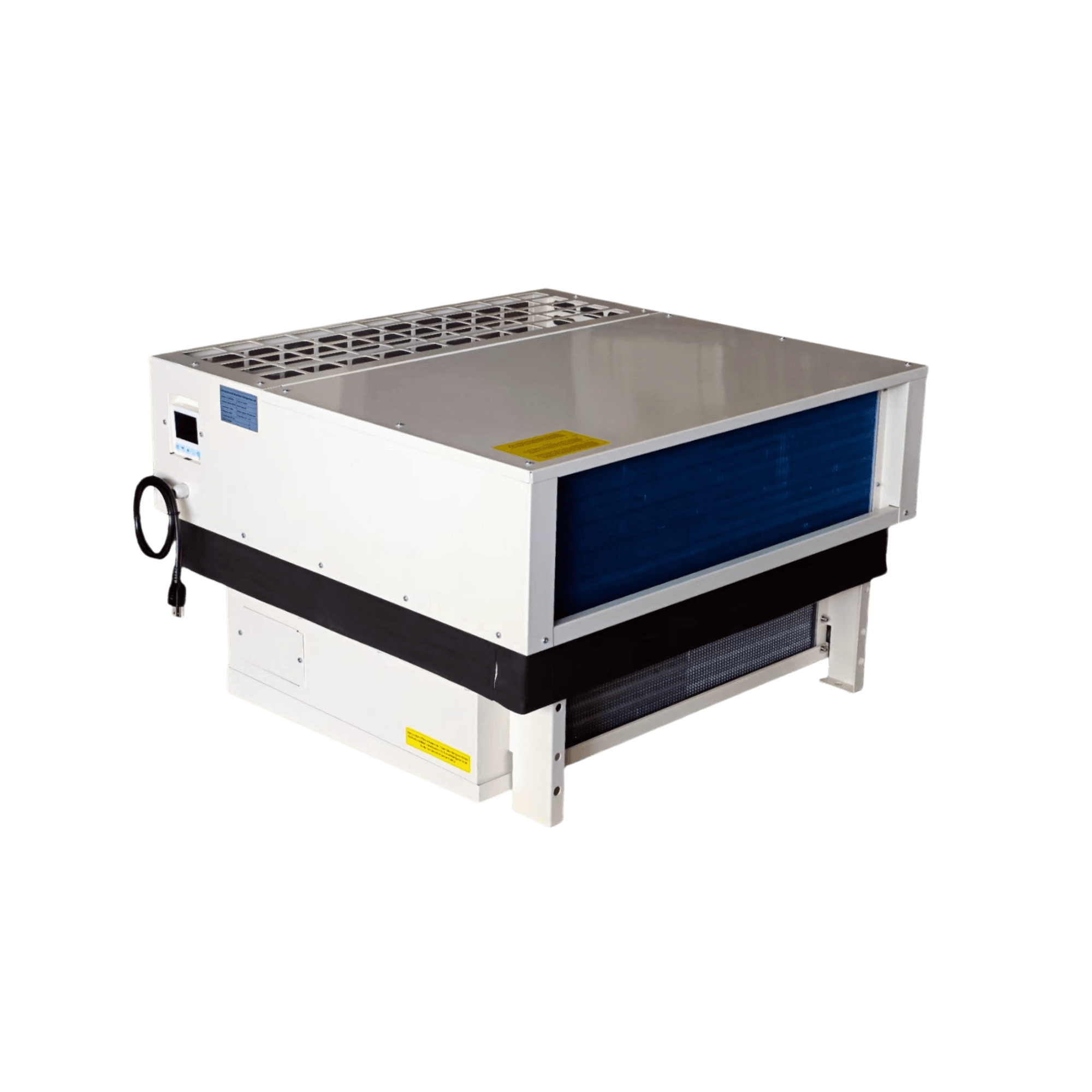

Features of Arctic Top-Mounted Monoblock

The Arctic Top-Mounted Monoblock is packed with features that set it apart from traditional cooling systems. Its compact design allows for easy installation, saving valuable space in your commercial kitchen or storage area. Additionally, this unit integrates both the compressor and evaporator into one seamless system, reducing potential points of failure and streamlining maintenance processes—an essential aspect when considering walk-in cooler compressor replacement options.

Another notable feature is its energy-efficient operation; this unit is designed to minimize energy consumption while maximizing cooling output. The advanced control systems allow precise temperature regulation, ensuring that your perishables are kept at optimal conditions without unnecessary energy waste. When you invest in a Commercial Freezer Compressor like this one, you're not just buying equipment; you're investing in reliability and sustainability.

Benefits for Walk In Coolers

One of the primary benefits of using the Arctic Active Cooling Unit in walk-in coolers is its ability to maintain consistent temperatures throughout the storage space. This is crucial for businesses storing sensitive products such as dairy or meats where temperature fluctuations can lead to spoilage and financial loss. Moreover, having a reliable walk-in cooler refrigeration unit means less downtime due to repairs—keeping your business running smoothly.

The integrated design also means fewer components to worry about when it comes time for a walk-in cooler compressor replacement. Since both the compressor and evaporator are housed within one unit, service technicians can address issues more efficiently than with separate systems that require extensive troubleshooting and repairs. Furthermore, customers often find that their overall walk-in cooler compressor replacement cost decreases due to reduced labor needs during maintenance.

Sustainable Cooling Solutions

Sustainability has become a vital consideration in today's business landscape—and rightly so! The Arctic Active Cooling Unit shines here by utilizing eco-friendly refrigerants and energy-efficient technology that significantly reduces environmental impact while keeping operational costs low. By choosing this system over traditional options like Commercial walk-in freezer compressors, businesses can contribute positively towards sustainability goals without sacrificing performance.

Moreover, these units are designed with durability in mind; they withstand heavy use while requiring minimal upkeep compared to older models or less efficient alternatives like standard cooler compressor units. Investing in sustainable solutions not only benefits your bottom line but also enhances your brand's reputation among environmentally-conscious consumers—a win-win scenario!

When to Call a Professional

Indicators That Require Expert Help

There are several telltale signs that suggest your commercial freezer compressor is in distress and requires professional attention. If you notice unusual noises, such as banging or hissing from your walk-in cooler compressor and evaporator, it's a clear signal that something's amiss. Additionally, if the temperature inside your cooler fluctuates significantly or fails to maintain the desired levels despite adjustments, it’s time to consult an HVAC technician.

Another red flag is if you detect any refrigerant leaks around the compressor unit; this not only affects performance but also poses safety hazards. If you've tried basic diagnostics—like checking power supply issues or examining temperature controls—without success, don't hesitate to call in a professional. Addressing these concerns promptly can prevent extensive damage and keep your walk-in cooler refrigeration unit running smoothly.

Finding a Reliable HVAC Technician

Finding a trustworthy HVAC technician for your commercial walk-in freezer compressor needs is crucial for effective repairs and maintenance. Start by seeking recommendations from fellow business owners or checking online reviews for local professionals who specialize in refrigeration units. Look for technicians who have experience specifically with walk-in coolers and possess relevant certifications; they’ll be more likely to handle any issues efficiently.

Once you've shortlisted potential candidates, don’t hesitate to ask questions regarding their experience with similar systems and their approach to troubleshooting problems like those affecting your cooler compressor unit. Transparency about pricing structures is also essential; make sure you understand how they charge for services before committing. A reliable technician will provide clear estimates on both repair costs and timelines so you won't be left in the dark.

Understanding Repair vs. Replacement Cost

When faced with issues related to your walk-in cooler compressor replacement needs, understanding whether repair or replacement is more cost-effective can be daunting yet vital for budgeting purposes. Generally speaking, if repairs are minor—like fixing an expansion valve—the costs will be significantly lower than replacing the entire commercial freezer compressor system altogether. However, if you're looking at major components needing replacement frequently or if the unit is over 10 years old, investing in a new refrigeration unit might be wise.

The average walk-in cooler compressor replacement cost varies depending on factors like brand compatibility and installation complexity; getting multiple quotes will help gauge fair pricing options available in your area. Remember that while initial costs may seem high when purchasing new equipment like an Arctic Active Cooling system—which boasts advanced efficiency—the long-term savings on energy bills could offset this expense over time. Ultimately, weighing immediate repair costs against future savings will lead you toward making an informed decision that benefits both operations and finances.

Conclusion

In conclusion, maintaining a fully operational compressor for walk-in cooler systems is essential for ensuring food safety and energy efficiency. Regular diagnostics and timely interventions can prevent costly breakdowns and extend the lifespan of your equipment. By understanding the key components of your walk-in cooler refrigeration unit, you can effectively troubleshoot issues before they escalate.

Key Steps for Compressor Troubleshooting

When troubleshooting a commercial freezer compressor, start with the basics: check the power supply and ensure that all connections are secure. Next, examine temperature controls to confirm they are set correctly and functioning as intended. If these initial steps don’t resolve the issue, inspect the condenser coils for obstructions that may hinder airflow—this is often where problems begin with a walk-in cooler compressor.

Importance of Regular Maintenance

Regular maintenance is crucial in preventing emergency repairs on your walk-in cooler compressor and evaporator systems. Scheduled inspections help identify potential issues early on, allowing you to address them before they lead to significant downtime or costly repairs like walk-in cooler compressor replacement. Additionally, routine cleaning and servicing improve overall efficiency, reducing energy consumption and prolonging the life of your commercial walk-in freezer compressor.

Enhancing Efficiency with Quality Equipment

Investing in high-quality equipment like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit can significantly enhance cooling performance while minimizing operational costs. These innovative units are designed specifically for commercial applications, ensuring optimal humidity control alongside temperature management—perfect for everything from food storage to fresh flower markets. When considering a walk-in cooler compressor replacement cost, remember that quality equipment not only reduces energy bills but also enhances reliability in critical cooling operations.