Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Walk-in coolers are essential for businesses that require precise temperature control for perishable goods, and understanding their components is vital for optimal performance. A crucial element of these systems is the walk-in cooler compressor, which plays a pivotal role in maintaining the desired temperature. In this guide, we will explore the significant components of walk-in coolers, particularly focusing on compressors and heat exchangers, to help you appreciate how they work together to keep your products fresh.

Understanding Walk-in Cooler Components

At the heart of every efficient walk-in cooler lies a series of interconnected components working in harmony to provide reliable cooling solutions. The primary players include the walk-in cooler compressor, evaporator coils, and heat exchangers—all designed to ensure that your goods remain at safe temperatures. By grasping what each component does, you can better understand how they contribute to the overall functionality and efficiency of your cooling system.

Importance of Compressors and Heat Exchangers

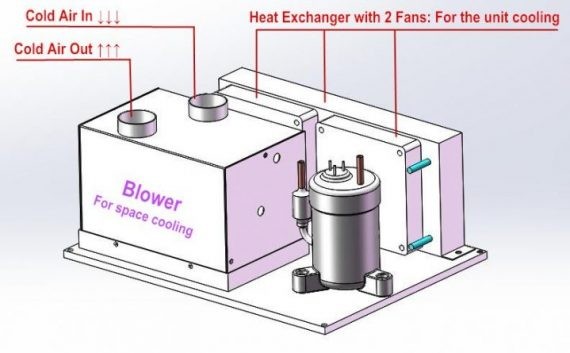

The walk-in cooler compressor serves as the engine behind the refrigeration cycle; it compresses refrigerant gas before sending it through coils where heat is expelled outside. Without a functioning compressor, your entire cooling system would falter—leading many business owners to ask, What type of compressor is a walk-in cooler? Alongside compressors, heat exchangers play an equally vital role by transferring heat away from refrigerated spaces; their synergy with compressors ensures effective cooling.

Functionality of Walk-in Cooler Systems

Understanding how these systems operate can help you make informed decisions about maintenance and potential upgrades. The interaction between the walk-in cooler compressor and evaporator is crucial; when working optimally, they create an efficient cooling cycle that minimizes energy consumption while maximizing performance. If you're wondering about costs associated with repairs or replacements—like How much is a new compressor for a walk-in cooler?—it's essential to factor in not just initial expenses but also long-term efficiency gains.

The Role of Walk-in Cooler Compressors

Walk-in cooler compressors are the unsung heroes of refrigeration systems, quietly working behind the scenes to keep your perishables fresh and cool. These devices play a pivotal role in maintaining the ideal temperature within walk-in coolers, ensuring that food and beverages are stored safely. Understanding their function is crucial for anyone operating a commercial kitchen or food storage facility.

What is a Cooler Compressor?

A cooler compressor is essentially the heart of a walk-in cooler system, responsible for compressing refrigerant gas and circulating it through the cooling system. This process cools down the air inside the unit, creating an optimal environment for food preservation. Without a reliable cooler compressor, your walk-in cooler would be little more than an expensive storage box with no climate control.

Types of Walk-in Cooler Compressors

When it comes to what type of compressor is a walk-in cooler, there are several options available to suit different needs. The most common types include reciprocating compressors, scroll compressors, and screw compressors; each has its own unique advantages and applications. Understanding these types can help you choose the right walk-in cooler compressor for your specific requirements.

Reciprocating compressors are known for their efficiency and reliability but can be noisy; scroll compressors offer quieter operation with fewer moving parts; screw compressors excel in larger systems requiring high capacity and efficiency. Depending on your operational needs and budget constraints, selecting the right type can make all the difference in performance and longevity.

How Much is a New Compressor for a Walk-in Cooler?

When considering replacement costs, you might wonder how much is a new compressor for a walk-in cooler? Prices can vary significantly based on brand, type, size, and efficiency rating but typically range from $1,000 to $3,000 or more—installation costs not included! It's important to factor in these expenses when budgeting for maintenance or upgrades to ensure consistent cooling performance.

Understanding both upfront costs and potential long-term savings from energy-efficient models will help you make an informed decision about your investment in a new walk-in cooler compressor. Additionally, don’t forget to consider any warranties or service agreements that could provide further peace of mind regarding your investment.

Heat Exchangers: The Unsung Heroes

When it comes to the efficiency of a walk-in cooler, heat exchangers play a pivotal role that often goes unnoticed. These components are essential for transferring heat between two or more fluids, ensuring that your walk-in cooler compressor operates at peak performance. Without effective heat exchange, even the best compressor would struggle to maintain the desired temperature.

How Heat Exchangers Work

Heat exchangers operate on the principle of thermal conduction, allowing heat to move from one fluid to another without mixing them. In a typical walk-in cooler system, the refrigerant absorbs heat from inside the cooler and transfers it outside through the heat exchanger. This process not only enhances cooling efficiency but also prolongs the life expectancy of a walk-in cooler compressor by preventing overheating.

Common Types of Heat Exchangers

There are several types of heat exchangers commonly used in refrigeration systems, including shell-and-tube, plate, and air-cooled models. Each type has its own unique advantages; for instance, shell-and-tube designs are excellent for high-pressure applications while plate exchangers offer superior surface area for efficient heat transfer in compact spaces. Understanding what type of compressor is a walk-in cooler can help you choose the right kind of heat exchanger that complements your system.

Importance of Heat Exchangers in Cooling

Heat exchangers are crucial because they directly impact how effectively your walk-in cooler compressor can function. By efficiently transferring excess heat away from the refrigerant, they ensure that cooling cycles remain optimal and energy consumption stays low. Consequently, neglecting these unsung heroes could lead to increased wear on your compressor and higher walk-in cooler compressor replacement costs down the line.

Life Expectancy of Walk-in Cooler Compressors

Understanding the life expectancy of a walk-in cooler compressor is crucial for any business relying on refrigeration. Typically, these compressors can last anywhere from 10 to 15 years with proper maintenance. However, neglecting routine upkeep can significantly shorten their lifespan, leading to unexpected breakdowns and costly repairs.

Average Lifespan and Maintenance

The average life expectancy of a walk-in cooler compressor hovers around 10 to 15 years, depending on usage and maintenance practices. Regular maintenance is essential; it includes cleaning coils, checking refrigerant levels, and inspecting electrical components. Neglecting these tasks can lead to premature failure, making it vital to schedule periodic service checks.

Routine maintenance not only extends the life of your walk-in cooler compressor but also ensures optimal performance. A well-maintained compressor operates more efficiently, which translates into lower energy bills over time. So remember: a little TLC goes a long way in keeping your cooling system running smoothly!

Factors Affecting Compressor Longevity

Several factors influence how long your walk-in cooler compressor will last, including operating conditions and load demands. For instance, if your cooler frequently operates at maximum capacity or experiences extreme temperature fluctuations, the wear and tear will be accelerated. Additionally, environmental factors such as humidity can also impact the efficiency and longevity of the compressor.

Another crucial factor is the type of compressor used in your system; some models are designed for heavy-duty use while others are more suited for light commercial applications. The quality of installation plays a significant role as well; improper installation can lead to inefficiencies that shorten lifespan dramatically. Understanding these variables helps you make informed decisions about what type of compressor is best for your needs.

Signs That Your Compressor Needs Replacement

Recognizing signs that your walk-in cooler compressor may need replacement can save you from costly downtime or spoilage issues down the line. Common indicators include unusual noises like grinding or rattling sounds—these could signal internal damage or wear within the unit itself. Additionally, if you notice inconsistent temperatures or frequent cycling on and off without reaching set levels, it's time to investigate further.

Another telltale sign is an increase in energy bills; if you're suddenly paying more for electricity without any changes in usage patterns, it could be due to an inefficient compressor struggling to keep up with demand. Lastly, if you've had multiple repairs within a short timeframe—especially concerning the walk-in cooler compressor and evaporator—it might be more cost-effective to consider replacement rather than ongoing repairs.

Keeping an eye out for these signs will help you stay ahead of potential issues and understand when it's time for that all-important walk-in cooler compressor replacement cost discussion!

Walk-in Cooler Compressor and Evaporator Interaction

The relationship between the walk-in cooler compressor and the evaporator is crucial for efficient cooling. These two components work in tandem to ensure that temperatures remain consistent, preserving the quality of stored goods. Understanding this interaction can help you troubleshoot issues and optimize your system's performance.

How They Work Together

The walk-in cooler compressor serves as the heart of the cooling system, compressing refrigerant gas and circulating it through the evaporator. The evaporator absorbs heat from inside the cooler, allowing cool air to circulate throughout the space. Together, they create a continuous cycle: as the compressor pushes refrigerant into the evaporator, it transforms back into a gas after absorbing heat, which then returns to the compressor for another round.

Impact on Cooling Efficiency

The efficiency of your walk-in cooler largely depends on how well your compressor and evaporator interact. If either component is underperforming or malfunctioning, it can lead to increased energy consumption and inconsistent temperatures—nobody wants spoiled inventory! Regular maintenance ensures that both parts are functioning optimally, which not only saves you money but also extends the life expectancy of a walk-in cooler compressor.

Common Issues in Compressor and Evaporator Systems

Several common issues can arise when dealing with walk-in cooler compressors and evaporators. For instance, if there's a refrigerant leak or blockage in the lines, it can significantly hinder performance, leading to higher replacement costs down the line. Additionally, inadequate airflow around either component can cause overheating or inefficient cooling cycles—both problems that could signal it's time for a walk-in cooler compressor replacement.

ARCTIC’s Innovations in Cooling Technology

ARCTIC has become a game-changer in the world of cooling technology, particularly when it comes to walk-in cooler compressors. With an emphasis on custom solutions tailored to individual needs, ARCTIC stands out by offering innovative designs that enhance efficiency and performance. Their commitment to quality ensures that businesses can rely on their systems for optimal cooling without breaking the bank.

Custom Cooling Solutions for Walk-in Coolers

When it comes to walk-in cooler compressors, one size definitely does not fit all. ARCTIC specializes in creating custom cooling solutions that cater specifically to the unique requirements of each business, whether it's a restaurant needing precise temperature control or a grocery store requiring robust refrigeration capabilities. By understanding what type of compressor is a walk-in cooler and how different environments affect performance, ARCTIC can design systems that maximize efficiency while minimizing energy costs.

These tailored solutions also take into account the interaction between the walk-in cooler compressor and evaporator, ensuring they work harmoniously together for peak performance. This level of customization not only enhances cooling efficiency but also extends the life expectancy of a walk-in cooler compressor by reducing unnecessary strain on components. Therefore, businesses can enjoy reliable refrigeration without worrying about frequent repairs or replacements.

Benefits of Choosing ARCTIC

Choosing ARCTIC means opting for reliability and innovation in your cooling systems. One significant benefit is their expertise in understanding replacement costs; they provide transparent pricing so you know exactly how much a new compressor for a walk-in cooler will set you back before making any decisions. This clarity helps businesses budget effectively while ensuring they invest in quality equipment that will last.

Moreover, with advancements in technology, ARCTIC's compressors offer features such as energy-efficient designs and smart monitoring capabilities that help reduce operational costs over time. The focus on sustainability ensures that customers are not just saving money but are also contributing positively to the environment—an aspect more businesses are prioritizing today. Ultimately, choosing ARCTIC means investing in cutting-edge technology that meets modern demands.

Customer Success Stories

ARCTIC's innovations have led to numerous success stories among businesses across various sectors looking for reliable walk-in cooler compressors. One notable example involves a local bakery that faced challenges with inconsistent temperatures affecting product quality; after switching to an ARCTIC custom solution, they reported improved temperature stability and reduced spoilage rates significantly within weeks!

Another success story includes a grocery store chain that needed efficient refrigeration systems due to rising operational costs; after implementing ARCTIC's advanced technologies, they saw substantial savings on their energy bills along with extended life expectancy of their walk-in cooler compressors—proving once again how crucial proper selection is when considering what type of compressor is suitable for specific applications.

These cases highlight not only the effectiveness of choosing ARCTIC but also reinforce the importance of understanding components like the evaporator and compressor interaction within your cooling system setup—a key takeaway for anyone considering upgrades or replacements.

Conclusion

In wrapping up our exploration of walk-in cooler compressors, it’s clear that these components are the backbone of any efficient cooling system. A walk-in cooler compressor not only plays a pivotal role in maintaining the desired temperature but also ensures the longevity and quality of stored products. Understanding what a cooler compressor is and its various types can help businesses make informed decisions about their cooling needs.

Recap of Compressor Importance

The importance of a walk-in cooler compressor cannot be overstated; it's essentially the heart of your refrigeration system. Without a reliable compressor, your walk-in cooler would struggle to maintain optimal temperatures, leading to potential spoilage and financial loss. Moreover, knowing how much a new compressor for a walk-in cooler costs can help you budget effectively for repairs or replacements when needed.

Understanding Replacement Costs

When considering the replacement costs associated with a walk-in cooler compressor, it's essential to factor in both the price of the unit itself and any installation fees. Typically, how much is a new compressor for a walk-in cooler? The answer varies based on brand and specifications but investing in quality often pays off in terms of efficiency and lifespan. Additionally, understanding what is the life expectancy of a walk-in cooler compressor can guide you on when to start budgeting for future replacements.

Future Trends in Cooling Technology

Looking ahead, advancements in cooling technology promise to enhance efficiency and sustainability in refrigeration systems like those used for walk-in coolers. Innovations such as smart compressors that optimize energy use or eco-friendly refrigerants are becoming increasingly popular among businesses aiming for greener operations. As we explore these trends, it’s crucial to stay informed about how they may impact your current setup—especially regarding your walk-in cooler compressor and evaporator interactions.