Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of temperature-sensitive storage, understanding the significance of a cold room compressor is crucial for maintaining optimal conditions. Regular maintenance not only enhances performance but also prolongs the lifespan of these vital systems, ensuring that your cold room operates efficiently. With various types of cold room compressors available, it’s essential to know which one suits your needs best.

Importance of Regular Maintenance

Regular maintenance for your cold room compressor is not just a good idea; it's essential for smooth operations and cost savings. Neglecting this critical task can lead to unexpected breakdowns and costly repairs, ultimately affecting your business's bottom line. By prioritizing maintenance, you ensure consistent temperature control and energy efficiency in your cooling systems.

What is a Cold Room Compressor?

A cold room compressor is an integral component in refrigeration systems that helps regulate temperature by compressing refrigerant gas and circulating it through the system. This process plays a vital role in keeping perishable goods fresh and safe from spoilage. Understanding what a cold room compressor does will help you make informed decisions about its maintenance and care.

Types of Cold Room Compressors

When it comes to refrigeration, there are several types of compressors to consider: reciprocating, scroll, screw, and centrifugal compressors are the four main categories that serve different applications within cold rooms. Each type has unique characteristics that make it suitable for specific environments or cooling demands. Knowing which compressor is best for your cold room can significantly impact efficiency and performance.

Understanding Your Cold Room Compressor

Understanding your cold room compressor is crucial for efficient operation and maintenance. A cold room compressor plays a vital role in the refrigeration cycle, ensuring that your perishable goods are stored at optimal temperatures. In this section, we will delve into how a cold compressor works, explore the four main types of refrigeration compressors, and determine which compressor is best for cold rooms.

How Does a Cold Compressor Work?

A cold compressor operates by compressing refrigerant gas, increasing its pressure and temperature before it enters the condensing units & compressors. This high-pressure gas then moves through the condenser coils where it releases heat and transforms into a liquid state. Once liquefied, the refrigerant flows through an expansion valve into the evaporator, absorbing heat from the surroundings to cool down the air inside your cold room.

The cycle continues as the low-pressure gas returns to the compressor to repeat this process. The efficiency of how well this system works directly impacts temperature control in your cold storage environment. Therefore, understanding how does a cold compressor work is essential for maintaining consistent temperatures and ensuring product quality.

What Are the 4 Types of Refrigeration Compressors?

When considering what are the 4 types of refrigeration compressors, it's important to recognize their unique functions and applications in various cooling systems. The four main types include reciprocating compressors, scroll compressors, screw compressors, and centrifugal compressors.

Reciprocating compressors use pistons driven by a crankshaft to compress refrigerant gases; they are common in smaller systems like domestic refrigerators or small cold rooms. Scroll compressors utilize two spiral-shaped scrolls to compress refrigerants more quietly and efficiently—ideal for mid-sized commercial applications such as restaurants or grocery stores with moderate cooling needs. Screw compressors are designed for larger industrial applications due to their ability to handle high capacities efficiently while centrifugal compressors utilize rotational energy from a rotating impeller to compress gases—best suited for large-scale operations requiring significant cooling power.

Which Compressor is Best for Cold Room?

Determining which compressor is best for your cold room depends on several factors including size requirements, energy efficiency needs, and specific application demands. For small-scale operations or those with limited space constraints, scroll or reciprocating compressors may be ideal due to their compact design and efficiency in maintaining desired temperatures effectively.

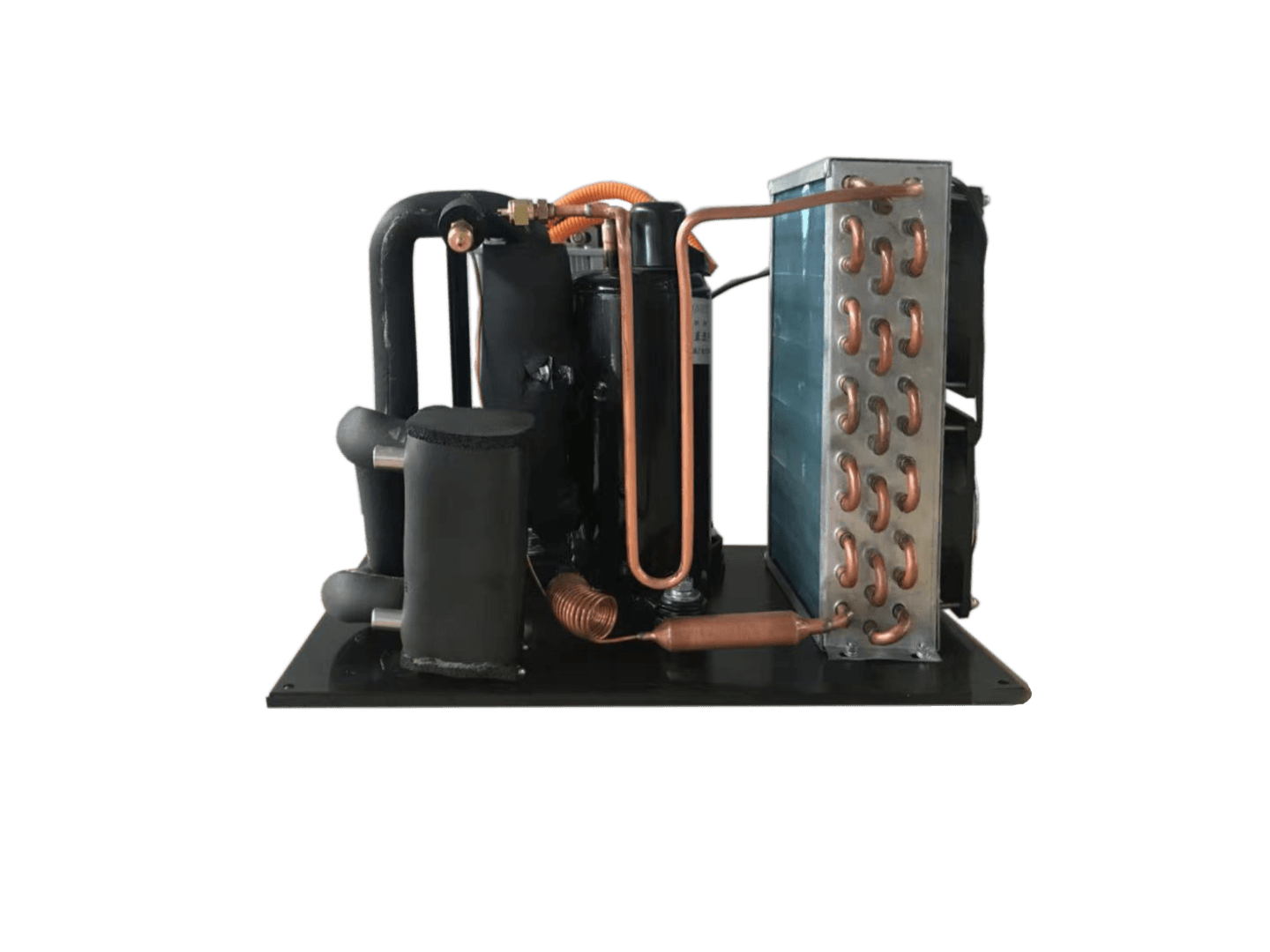

On the other hand, if you operate a large commercial facility requiring robust cooling solutions over extended periods without interruption, consider investing in screw or centrifugal models that can provide higher capacity while remaining energy-efficient over time. Additionally, brands like Arctic Active Cooling offer advanced options with their Top-Mounted Monoblock Refrigeration Unit that combines performance with convenience—perfectly suited for businesses looking to optimize their cooling capabilities while minimizing operational costs.

Signs Your Compressor Needs Attention

Keeping an eye on your cold room compressor is crucial for maintaining optimal performance and efficiency. There are several signs that indicate your compressor may need attention, which can help you avoid costly repairs or replacements down the line. Recognizing these symptoms early can save you time, money, and headaches.

Unusual Noise and Vibrations

If your cold room compressor is making strange noises or vibrating excessively, it’s time to investigate further. Normal operation should be relatively quiet; any unusual sounds—like grinding, clanking, or buzzing—can signal mechanical issues within the unit. Additionally, excessive vibrations may indicate loose components or mounting problems that could lead to further damage if not addressed promptly.

These noises might also affect the overall performance of your cold room chiller unit, causing fluctuations in temperature control. If you're wondering which compressor is best for a cold room, one that operates smoothly and quietly should be a top consideration. Regular maintenance can help prevent these noise issues by ensuring all parts are functioning correctly.

Inconsistent Temperature Control

This inconsistency not only affects product quality but also increases energy consumption as the system struggles to maintain desired conditions. If you're asking yourself what are the 4 types of refrigeration compressors?—you'll find that some types are better suited for specific applications than others when it comes to maintaining stable temperatures in a cold room environment. Choosing wisely here will help ensure consistent performance.

Increased Energy Bills

A sudden spike in energy bills can often serve as a wake-up call regarding your cold room compressor's condition. When compressors struggle due to inefficiencies—whether from wear and tear or inadequate maintenance—the amount of energy they consume typically rises significantly. This increase might have you questioning what is a cold room compressor? It's essential to remember that efficient operation directly correlates with lower energy costs.

If you've noticed higher bills without any changes in usage patterns, it's wise to investigate potential underlying issues with your condensing units & compressors immediately before costs spiral out of control further still! Regular checks on refrigerant levels and overall system efficiency will keep those bills manageable while extending the lifespan of your equipment too!

Benefits of Regular Maintenance

Maintaining your cold room compressor is not just a good idea; it’s essential for optimal performance. Regular maintenance can significantly enhance the efficiency and reliability of your cooling system, ensuring that it operates at its best. By keeping your equipment in top shape, you can avoid costly breakdowns and enjoy peace of mind.

Enhancing Efficiency and Performance

One of the primary benefits of regular maintenance on a cold room compressor is improved efficiency. When components like condensing units and compressors are clean and well-maintained, they operate more smoothly, consuming less energy while providing consistent cooling. This means that not only will you save on energy bills, but you'll also be able to better control temperatures—an essential factor for any cold room.

Additionally, understanding how does a cold compressor work can help you appreciate the intricacies involved in maintaining its performance. For instance, routine checks ensure that refrigerant levels are optimal and that there are no leaks or blockages impeding airflow. Ultimately, this leads to enhanced performance and reliability over time.

Prolonging Equipment Lifespan

Regular maintenance plays a crucial role in prolonging the lifespan of your cold room chiller unit. Just like any other machine, neglecting routine upkeep can lead to premature wear and tear on critical components such as compressors and condensing units. By investing time in regular inspections and servicing, you're effectively extending the operational life of your equipment.

Moreover, knowing what is a cold room compressor helps you understand its importance in food storage or industrial applications where temperature control is vital. When these systems are maintained properly, they tend to withstand wear better than those left unattended—saving you from unexpected replacements down the line. In short, treating your equipment with care is an investment in longevity.

Reducing Repair Costs

Another compelling reason for regular maintenance is cost savings through reduced repair expenses. When small issues are identified early during routine checks on your cold room compressor or its associated components like condensing units & compressors, they can often be resolved before escalating into major problems requiring expensive repairs or even replacements.

Additionally, if you’re pondering which compressor is best for cold room applications based on long-term costs versus upfront investments, proper maintenance tips the scales towards lower overall expenses over time due to fewer breakdowns and repairs needed down the road. This proactive approach not only saves money but also minimizes downtime—keeping your operations running smoothly without interruptions.

In conclusion, prioritizing regular maintenance for your cold room compressor brings numerous benefits including enhanced efficiency and performance; prolonged lifespan; and reduced repair costs—all crucial elements for any business relying on effective refrigeration solutions like Arctic Active Cooling’s innovative Top-Mounted Monoblock Refrigeration Unit designed specifically for modern cooling needs.

Steps for Effective Maintenance

To ensure your cold room compressor operates at peak efficiency, regular maintenance is essential. By following a structured maintenance routine, you can extend the lifespan of your equipment and avoid costly repairs. Here are some key steps to keep in mind when caring for your cold room compressor.

Cleaning Condensing Units and Compressors

Cleaning the condensing units and compressors is a crucial step in maintaining your cold room compressor. Dust and debris can accumulate, leading to reduced airflow and inefficient cooling performance. Regularly inspect these components, removing any obstructions to ensure that air circulation remains optimal for effective heat exchange.

Furthermore, cleaning not only enhances the efficiency of your cold room chiller unit but also prevents overheating issues that could lead to compressor failure. A clean compressor will operate more smoothly, reducing wear and tear over time. So grab that vacuum or brush and give those condensing units the attention they deserve!

Checking Refrigerant Levels

Understanding how a cold compressor works involves monitoring refrigerant levels closely, as they are vital for efficient operation. Low refrigerant levels can indicate leaks or other issues affecting cooling performance in your cold room compressor. Regular checks help you identify problems early on before they escalate into major repairs.

If you find that refrigerant levels are low, it’s essential to consult with professionals who can determine whether it’s simply a refill or if there's a leak needing attention. Remember, maintaining the right refrigerant levels not only ensures optimal temperature control but also contributes to energy savings in your operation—goodbye high bills!

Inspecting Electrical Components

Electrical components play an integral role in how well your cold room compressor functions; hence regular inspections are necessary. Look out for frayed wires, loose connections, or any signs of corrosion which could compromise performance or safety. Ensuring these elements are in good condition helps prevent unexpected breakdowns and prolongs equipment lifespan.

Additionally, checking electrical components aids in identifying potential hazards early on—nobody wants their cooling system to fail during peak business hours! If you're unsure about what to look for or how to perform these inspections safely, consider reaching out to professionals who specialize in refrigeration systems like Arctic Active Cooling for expert guidance.

Choosing the Right Cold Room Chiller Unit

Selecting the right cold room chiller unit is crucial for maintaining optimal temperature and efficiency in your refrigeration system. A well-chosen cold room compressor can significantly impact your energy consumption and product preservation. This section will guide you through essential features to look for, top brands to consider, and the innovative solutions offered by Arctic Active Cooling.

Features to Look For

When evaluating a cold room chiller unit, start by considering its cooling capacity and efficiency ratings. Look for a unit that effectively meets your specific needs, whether you're storing perishable goods or sensitive materials. Additionally, features such as adjustable temperature controls, easy maintenance access, and noise reduction technology can enhance performance while ensuring a quieter environment.

Another critical aspect is the type of refrigerant used in the cold room compressor; environmentally friendly options are becoming increasingly important in today’s market. Make sure the compressor has reliable safety features to prevent overheating or leaks during operation. Lastly, check if it includes advanced monitoring systems that provide real-time data on temperature fluctuations and energy consumption.

Top Brands to Consider

Several reputable brands stand out when it comes to cold room compressors and chillers. Companies like Carrier, Trane, and Copeland are known for their high-quality refrigeration solutions tailored for various applications. Each brand offers a range of models designed with different capacities and features suited for diverse commercial needs.

Another noteworthy mention is Arctic Active Cooling, which specializes in advanced cooling technologies with their Top-Mounted Monoblock Refrigeration Unit. This innovative solution combines convenience with performance for small to mid-sized cold rooms while ensuring sustainability through energy-efficient designs. When selecting a brand, always consider customer reviews and after-sales support as they play an essential role in your long-term satisfaction.

The Role of Arctic Active Cooling

Arctic Active Cooling takes pride in providing cutting-edge solutions tailored specifically for modern cooling challenges faced by businesses today. Their Top-Mounted Monoblock Refrigeration Unit exemplifies this commitment by delivering unparalleled efficiency without compromising on reliability or ease of use. Designed for commercial refrigerators and freezers alike, this unit ensures optimal humidity control—a crucial factor when storing sensitive items like fresh flowers.

Furthermore, Arctic Active Cooling's products are engineered with sustainability in mind; they help businesses reduce their carbon footprint while maintaining high-performance standards in their refrigeration systems. By investing in an Arctic Active Cooling solution, you’re not just purchasing a cold room chiller unit; you’re embracing innovation that enhances operational efficiency while preserving valuable resources.

Conclusion

In conclusion, the health of your cold room compressor should never be underestimated. Regular maintenance not only enhances performance but also prolongs the lifespan of your equipment, ensuring that it operates at peak efficiency. By prioritizing your compressor's health, you can avoid costly repairs and keep your cold room functioning smoothly.

Prioritize Your Compressor's Health

Understanding what a cold room compressor is and how it functions is crucial for any business relying on refrigeration systems. Regular check-ups can help identify issues early, such as unusual noise or inconsistent temperature control—two signs that your compressor may need attention. Remember, a well-maintained cold room compressor not only keeps your products safe but also saves you money in the long run.

Invest in Professional Maintenance Services

While some maintenance tasks can be handled in-house, investing in professional maintenance services ensures that all aspects of your cold room chiller unit are properly addressed. Trained technicians understand which compressor is best for cold rooms and can offer insights into the four types of refrigeration compressors available today. They’ll check everything from condensing units & compressors to refrigerant levels, giving you peace of mind that your system is running optimally.

Explore Advanced Cooling Solutions

If you're looking to upgrade or replace existing equipment, exploring advanced cooling solutions like Arctic Active Cooling could be a game-changer for your business. Their innovative Top-Mounted Monoblock Refrigeration Unit offers exceptional efficiency and reliability tailored for modern applications, including those requiring precise temperature control for items like fresh flowers. Investing in cutting-edge technology not only enhances performance but also aligns with sustainability goals—making it an excellent choice for any business focused on reducing its environmental footprint.