Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of lasers, efficient cooling is not just an optional feature; it's a necessity that can dictate the performance and longevity of your equipment. Understanding the role of cooling in lasers, particularly CO2 lasers, is crucial for anyone involved in laser operations or manufacturing. A well-designed laser water chiller plays a pivotal role in maintaining optimal temperatures, ensuring that your laser operates at peak efficiency.

Understanding the Role of Cooling in Lasers

The heat produced can lead to performance degradation or even damage if not properly managed. This is where a laser water chiller comes into play—providing consistent temperature control and enhancing overall system reliability.

The Mechanics of CO2 Laser Operation

CO2 lasers operate by exciting gas molecules within a sealed chamber, generating light through stimulated emission. However, as this process generates heat, it becomes essential to implement effective cooling solutions to prevent overheating and ensure optimal output quality. Understanding this mechanical process helps clarify why investing in a quality CO2 laser water chiller is vital for maintaining operational integrity.

Why Efficient Cooling Matters

Efficient cooling directly impacts not only the lifespan but also the performance of your CO2 laser system. Without proper temperature regulation, you risk reduced cutting speeds and compromised accuracy—two critical factors in industrial applications and precision work. Therefore, knowing when you need a water chiller for your CO2 laser can save you time and money while maximizing productivity.

What is a Laser Water Chiller?

When diving into the world of laser technology, understanding what a laser water chiller is becomes essential. A laser water chiller is a specialized cooling unit designed to maintain optimal temperatures for CO2 lasers during operation. By regulating temperature, these chillers help prevent overheating, ensuring consistent performance and extending the lifespan of the equipment.

Definition and Purpose

At its core, a laser water chiller is a mechanical device that circulates chilled water through the laser system to absorb excess heat generated during operation. The purpose of this cooling mechanism is to keep the laser components at stable temperatures, which is crucial for achieving precise cuts and engravings. Without an efficient cooling system in place, CO2 lasers can suffer from performance degradation or even damage due to overheating.

How It Supports CO2 Laser Performance

The integration of a CO2 laser water chiller directly impacts the efficiency and accuracy of your laser operations. When the temperature remains controlled, it allows for better beam quality and consistency in cutting or engraving tasks. Additionally, maintaining optimal temperatures can significantly reduce downtime caused by overheating issues, leading to improved productivity in industrial settings where time is money.

Common Misconceptions

One common misconception about laser water chillers is that they are only necessary for high-powered lasers or industrial applications; however, even lower-powered systems can benefit from proper cooling solutions. Another myth suggests that all cooling systems are created equal—this isn't true as different setups serve unique purposes depending on their design and application needs. Lastly, some users believe that investing in a high-quality CO2 laser water chiller isn't worth it; yet, considering its role in maximizing performance and prolonging equipment life makes it an essential investment.

Do I Need a Water Chiller for My CO2 Laser?

Signs That Indicate You Need One

If you notice frequent overheating or inconsistent performance from your CO2 laser, these are strong indicators that a water chiller may be necessary. Other signs include reduced cutting speed or quality, as well as increased wear on components due to heat stress. Additionally, if you're operating in an environment with varying ambient temperatures, investing in a reliable CO2 laser water chiller could stabilize performance and enhance productivity.

Benefits of Using a CO2 Laser Water Chiller

The benefits of using a CO2 laser water chiller extend beyond mere temperature control; they also encompass improved efficiency and output quality. By maintaining optimal temperatures, these chillers can help prolong the life of your equipment and reduce costly downtime due to overheating issues. Moreover, with advanced models like Arctic Active Cooling's Mini Water Chiller, users benefit from sophisticated designs that integrate seamlessly with existing systems for enhanced cooling solutions.

Cost vs. Benefit Analysis

When evaluating whether to invest in a laser water chiller, consider both upfront costs and long-term savings on repairs and maintenance. While the initial investment might seem steep, the potential reduction in operational disruptions can lead to significant cost savings over time. Furthermore, high-quality systems like Arctic Active Cooling's Mini Water Chiller offer features designed for efficiency and ease of integration, making them an attractive option for those looking to maximize their return on investment while ensuring their lasers operate at peak performance.

What is the Difference Between Chiller and Water Cooling?

Distinctions Explained

A laser water chiller operates by circulating chilled water through the laser's components, effectively removing heat generated during operation. This specialized equipment is engineered with features that cater specifically to the demands of high-performance lasers, ensuring consistent cooling even under heavy loads. In contrast, general water cooling systems may not offer the same level of precision or efficiency required for sensitive equipment like CO2 lasers.

Moreover, while both systems utilize water as a coolant, chillers often include refrigeration units that allow them to achieve lower temperatures than standard water cooling methods can provide. This capability makes them ideal for environments where heat buildup could compromise performance or lead to equipment failure. Understanding these differences helps users make informed decisions about their specific needs in high-temperature scenarios.

Advantages of Each System

The primary advantage of using a CO2 laser water chiller lies in its ability to maintain stable operating temperatures over extended periods, which is crucial for consistent performance and longevity of the laser itself. These units are designed with advanced features such as temperature monitoring and adjustable settings that allow users to fine-tune their cooling solutions based on operational demands. For those who frequently push their lasers to the limit, investing in a dedicated chiller can prevent overheating issues that might arise from prolonged use.

On the other hand, traditional water cooling systems may be more cost-effective and easier to install for less demanding applications. They work well in situations where extreme precision isn't necessary but still provide adequate thermal management for various machinery and tools beyond just lasers. Depending on your operational requirements and budget constraints, either option could serve your needs effectively.

Best Applications for Each

Laser water chillers are best suited for industrial applications involving CO2 lasers that require precise temperature control during cutting or engraving processes. These environments often demand high power levels where even slight increases in temperature can lead to significant performance degradation or damage over time; thus, having an efficient chilling system becomes paramount. Additionally, they are ideal for research labs or production facilities where consistent results are critical.

Conversely, general water cooling systems find their place across multiple industries—from HVAC units to automotive engines—where moderate thermal regulation suffices without needing specialized equipment like those found in laser operations. Their versatility allows them to adapt easily across different contexts but may fall short when extreme accuracy is needed as with high-powered lasers or sensitive electronics.

In summary, understanding what is the difference between chiller and water cooling helps you choose wisely based on your specific application needs—whether you're looking into best practices surrounding industrial water cooling solutions or exploring options like Arctic Active Cooling's Mini Water Chiller designed specifically for micro-cooling tasks.

Exploring the Best Water Cooling Systems

Overview of Top Models and Brands

Several brands have established themselves as leaders in manufacturing effective laser water chillers tailored for CO2 lasers. Notable names include ChillX, ThermoTek, and Arctic Active Cooling, each offering a range of models designed to meet varying cooling needs. These brands provide options that cater to both industrial applications and smaller setups, ensuring there's something for everyone looking to optimize their laser's performance.

Key Features to Look For

When evaluating the best water cooling systems for your CO2 laser, there are several key features you should consider. First, look for a unit with adjustable temperature settings to maintain optimal cooling conditions based on your specific requirements. Additionally, a reliable flow rate is essential; too low can lead to overheating issues while too high may cause inefficiencies in operation.

Another crucial feature is energy efficiency; a well-designed laser water chiller will save you money over time by consuming less power while providing effective cooling solutions. Lastly, ease of maintenance should not be overlooked—systems that are easy to clean and service will save you time and hassle in the long run.

How Arctic Active Cooling Stands Out

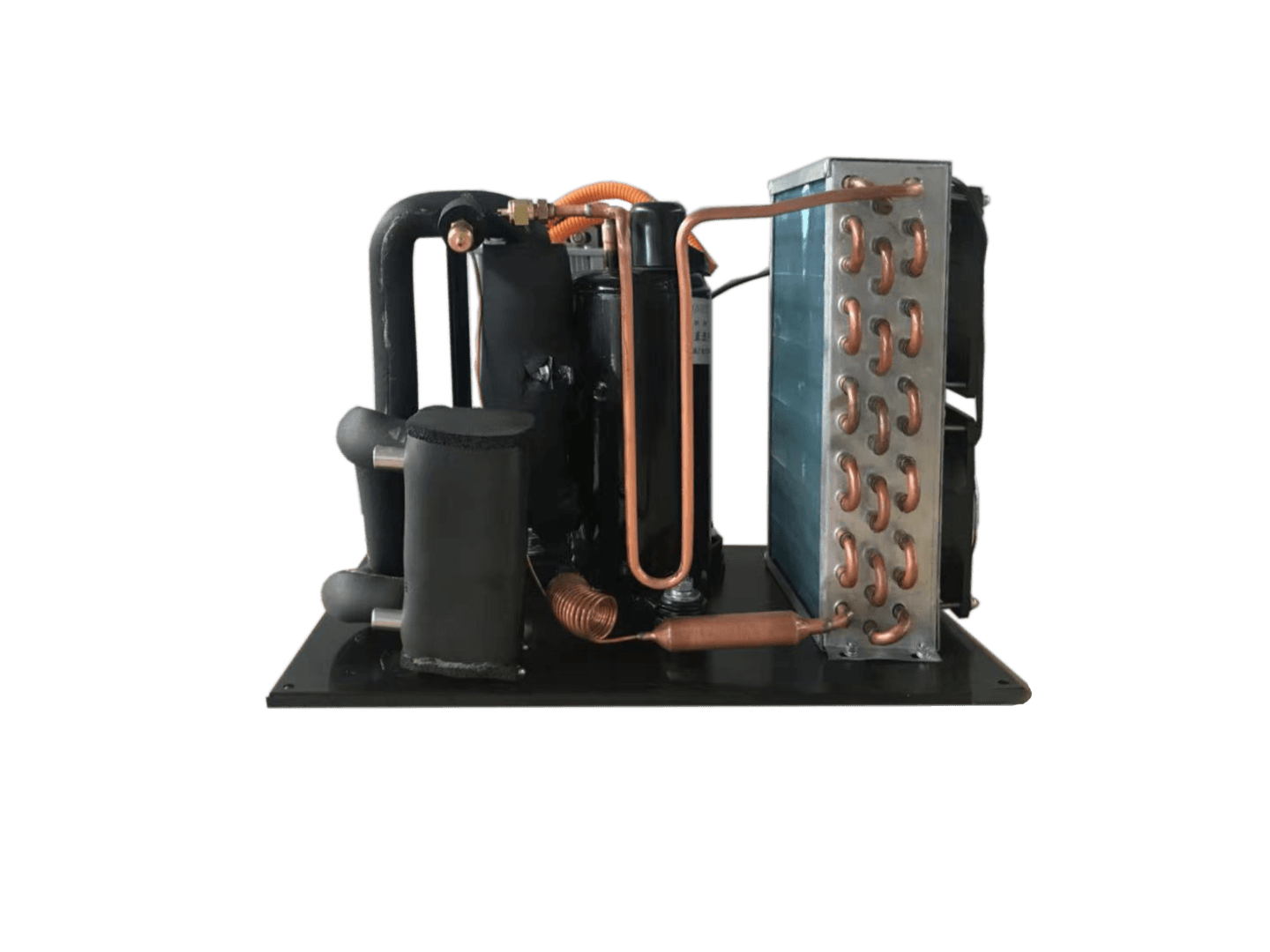

Arctic Active Cooling has carved out a niche in the market with its Mini Water Chiller—a compact yet powerful solution specifically designed for those who need efficient micro cooling systems for their CO2 lasers. This innovative unit combines a high-efficient refrigeration mini compressor with R134a coolant along with other essential refrigeration components into one sophisticated design by skilled engineers.

What sets Arctic Active Cooling apart is its focus on modularity; customers who prefer integrating or assembling their subsystems can easily connect their control boards with Arctic's BLDC compressor driver board for optimal performance management. This flexibility makes it an attractive choice not only for OEM projects but also for those looking into ODM solutions in industrial water cooling applications.

Industrial Water Cooling Solutions

In the realm of industrial applications, the significance of effective cooling systems cannot be overstated. Industrial water cooling solutions play a pivotal role in ensuring that equipment operates within optimal temperature ranges, thereby enhancing performance and longevity. A laser water chiller, for instance, is essential in high-volume settings where CO2 lasers are frequently used for cutting or engraving materials.

Importance in High-Volume Settings

High-volume settings often require continuous operation of machinery to meet production demands, making efficient cooling a necessity. Without proper temperature regulation provided by systems like a CO2 laser water chiller, overheating can lead to equipment failure and costly downtime. Thus, investing in a reliable laser water chiller becomes crucial for maintaining productivity and minimizing operational disruptions.

Applications Beyond CO2 Lasers

While CO2 lasers are perhaps the most recognized users of laser water chillers, these cooling solutions find applications across various industries. From medical devices requiring precise temperature control to manufacturing processes involving CNC machines and injection molding equipment, industrial water cooling is indispensable. Furthermore, as industries evolve and technology advances, the versatility of laser water chillers is increasingly recognized beyond traditional uses.

Future Trends in Industrial Cooling

The future of industrial cooling looks promising with innovations aimed at enhancing efficiency and sustainability. Emerging technologies focus on reducing energy consumption while improving performance metrics for systems like the best water cooling systems available today. Companies such as Arctic Active Cooling are leading this charge with products like their Mini Water Chiller; it features advanced components that integrate seamlessly into existing setups while offering customizable control options tailored to specific needs.

Conclusion

In the world of lasers, particularly CO2 lasers, the importance of efficient cooling cannot be overstated. A laser water chiller plays a crucial role in maintaining optimal operating temperatures, ensuring that your laser system runs smoothly and effectively. By understanding what a laser water chiller is and how it integrates with your CO2 laser setup, you can make informed decisions that enhance performance and longevity.

The Essential Role of Water Chillers

Water chillers are indispensable for any serious CO2 laser user seeking to maximize their equipment's potential. They help dissipate heat generated during operation, preventing overheating that could lead to costly repairs or reduced efficiency. Essentially, a reliable CO2 laser water chiller safeguards your investment by prolonging the life of the laser components while enhancing overall performance.

Maximizing Laser Efficiency with Cool Solutions

The right cooling solution can significantly improve the efficiency of your CO2 laser operation. A well-functioning water chiller ensures consistent temperatures, which translates into better precision and quality in cutting or engraving tasks. Moreover, by addressing common questions like Do I need a water chiller for my CO2 laser? users can better understand how these systems contribute to achieving superior results in their projects.

Investing in Quality Cooling Systems

When it comes to choosing between various options available on the market, investing in high-quality systems like Arctic Active Cooling's Mini Water Chiller can make all the difference. This innovative product offers sophisticated design features that integrate all necessary refrigeration components into one compact unit, making installation straightforward and efficient. For those looking for flexibility, this system allows customers to control compressor speed through their own control boards—perfect for tailored cooling solutions.