Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the rapidly evolving landscape of data centers, efficient cooling solutions have become paramount to maintaining optimal performance and sustainability. One such innovative approach is direct-to-chip liquid cooling, a technology that promises to enhance thermal management while reducing energy consumption. As data centers continue to scale, understanding what direct liquid cooling to chip entails and its implications for operational efficiency is essential.

Understanding Direct-to-Chip Liquid Cooling

So, what is direct-to-chip liquid cooling? This cutting-edge method involves circulating coolant directly to the components of a server or computing unit, effectively managing heat generated by high-performance processors. Unlike traditional air cooling systems, which can struggle with the thermal demands of modern hardware, direct-to-chip systems deliver superior temperature regulation and reliability.

The Rise of Efficient Data Center Cooling

The rise of efficient data center cooling solutions has been driven by increasing energy costs and environmental concerns. As organizations seek ways to optimize their operations while minimizing their carbon footprint, technologies like direct-to-chip liquid cooling have gained traction. This shift not only addresses immediate thermal challenges but also aligns with long-term sustainability goals in the industry.

Why Advanced Cooling Matters

Advanced cooling methods are crucial for several reasons: they enhance performance, extend hardware longevity, and significantly reduce operational costs. Understanding the benefits of direct-to-chip cooling can help decision-makers implement strategies that leverage these advancements effectively. Moreover, as we explore different types of liquid cooling options for data centers—including immersion systems—it's clear that having a grasp on these technologies will shape future infrastructure investments.

What is Direct-to-Chip Liquid Cooling?

Direct-to-chip liquid cooling is a cutting-edge technology designed to enhance the thermal management of data center components by directly cooling the chips themselves. This method involves circulating liquid coolant through cold plates that are attached to the chips, allowing for efficient heat transfer away from high-performance processors and other critical components. By doing so, it addresses the growing need for effective cooling solutions in an era where data centers are increasingly pushing the limits of performance and energy efficiency.

Defining the Technology

So, what is direct liquid cooling to chip? Essentially, it's a system that utilizes a liquid coolant instead of air to manage heat generated by electronic components. This approach allows for much higher thermal conductivity compared to traditional air cooling methods, which can struggle with heat dissipation as component density increases. As such, direct-to-chip liquid cooling represents a significant advancement in how we manage heat in high-density computing environments.

Components of Direct-to-Chip Systems

A typical direct-to-chip liquid cooling system comprises several key components working in harmony. These include cold plates that interface directly with chips, pumps to circulate coolant, and heat exchangers that transfer absorbed heat away from the system. The integration of these elements creates an efficient loop that ensures optimal temperature regulation—essential for maintaining performance and reliability in data centers.

Applications in Data Centers

What is direct-to-chip liquid cooling for data centers? Its applications are vast and varied; from high-performance computing (HPC) clusters to AI workloads requiring substantial processing power, this technology fits right into modern data center architectures. Organizations looking to improve energy efficiency while maximizing hardware longevity find that direct-to-chip systems offer compelling benefits over traditional methods—making them an attractive option as they scale up their operations.

The benefits of direct-to-chip cooling extend beyond just enhanced thermal management; they also include significant energy savings and operational cost reductions over time. Moreover, as companies increasingly prioritize sustainability initiatives, adopting advanced cooling solutions becomes essential for meeting environmental goals while ensuring peak performance.

Benefits of Direct-to-Chip Cooling

Direct-to-chip liquid cooling is revolutionizing the way data centers manage heat, and it brings a plethora of benefits that cannot be overlooked. Understanding what is direct liquid cooling to chip reveals its robust capabilities in enhancing efficiency and performance. As data centers grow in size and complexity, the advantages of direct-to-chip cooling become increasingly critical.

Enhanced Thermal Management

One of the standout features of direct-to-chip liquid cooling is its ability to provide enhanced thermal management. This technology allows for precise temperature control at the chip level, ensuring optimal performance without overheating. By utilizing dedicated coolant channels directly on chips, it effectively dissipates heat more efficiently than traditional air-cooling methods.

In essence, this means that data centers can push their hardware to higher performance levels without worrying about thermal throttling. The question often arises: what are the benefits of direct-to-chip cooling? Enhanced thermal management not only improves computing power but also increases overall system stability and reliability.

Energy Efficiency and Cost Savings

Energy efficiency is another significant advantage offered by direct-to-chip liquid cooling systems. Compared to conventional air-cooling solutions, these systems consume considerably less energy while maintaining optimal temperatures for high-performance computing tasks. This reduction in energy consumption translates into substantial cost savings over time.

Moreover, as energy costs continue to rise globally, implementing direct liquid cooling can serve as a proactive measure for data centers looking to reduce their operational expenses. With growing concerns about sustainability in tech industries, adopting efficient solutions like this positions organizations as environmentally conscious leaders while also benefiting their bottom line.

Improved Hardware Longevity

When considering what is direct-to-chip liquid cooling for data centers, one cannot ignore its positive impact on hardware longevity. By maintaining lower operating temperatures, this technology significantly reduces wear and tear on critical components such as CPUs and GPUs. Consequently, organizations can expect extended lifespans for their equipment.

This improvement in hardware longevity not only minimizes replacement costs but also contributes to a more sustainable approach by reducing electronic waste generated from frequent upgrades or replacements. In a world where technology evolves rapidly but sustainability remains paramount, investing in reliable solutions like direct-to-chip cooling becomes essential for future-proofing operations.

Direct-to-Chip vs. Immersion Cooling

Exploring the Differences

Direct-to-chip liquid cooling focuses on delivering coolant directly to the heat-generating components of servers, allowing for precise thermal management. This method involves using specialized cold plates or heat exchangers that are installed on CPUs and GPUs, effectively removing heat right at the source. On the other hand, immersion cooling submerges entire server racks in a thermally conductive liquid, which absorbs heat from all components simultaneously—think of it as giving your hardware a luxurious spa day!

The fundamental difference lies in how each system interacts with hardware: direct-to-chip systems provide targeted cooling while immersion systems offer blanket coverage. Additionally, direct-to-chip liquid cooling tends to require more complex integration with existing infrastructure compared to immersion setups, which can be more straightforward but may present challenges in terms of maintenance and accessibility.

Pros and Cons of Each Method

What are the benefits of direct-to-chip cooling? For starters, this method boasts enhanced thermal management capabilities that lead to improved energy efficiency and reduced operational costs—definitely a win-win! Furthermore, since it cools components directly, there's less risk of overheating and better overall performance for high-density computing tasks.

Conversely, immersion cooling has its perks too; it often requires less energy due to its ability to use passive heat transfer methods. However, one downside is that full immersion can complicate repairs or upgrades since accessing submerged components isn't as easy as reaching for a server in a traditional rack setup. So while both methods have their advantages and drawbacks, choosing between them ultimately depends on specific use cases and organizational goals.

Use Cases and Suitability

When evaluating what is direct liquid cooling system best suited for your needs, consider factors such as space constraints and server density. Direct-to-chip liquid cooling is particularly beneficial in environments where high-performance computing (HPC) is essential—like AI research labs or financial trading firms—where every degree matters! Its precision makes it ideal for applications requiring consistent temperature control without sacrificing performance.

On the flip side, immersion cooling may appeal more to organizations looking for an all-in-one solution that simplifies maintenance efforts while still providing robust thermal management capabilities. Data centers with limited space might find this method attractive because it allows for higher density configurations without overheating concerns—a true space-saver! Ultimately, both options serve distinct purposes within the broader landscape of Liquid Cooling Options for Data Centers.

Liquid Cooling Options for Data Centers

As data centers continue to evolve, the need for advanced cooling solutions becomes increasingly critical. Among these, direct-to-chip liquid cooling stands out as a powerful option that addresses the thermal management challenges faced by modern computing environments. In this section, we will explore various liquid cooling options available for data centers, focusing on their configurations and market players.

Overview of Available Solutions

When it comes to liquid cooling options for data centers, several solutions are available that cater to diverse needs and preferences. Direct-to-chip liquid cooling is one of the most effective methods, allowing for efficient heat removal directly from the components themselves. Other solutions include immersion cooling and traditional air-cooling systems; however, many are now looking into what is direct liquid cooling to chip? This method boasts numerous benefits and can significantly enhance data center performance.

The advantages of direct-to-chip systems lie in their ability to provide enhanced thermal management while minimizing energy consumption. What are the benefits of direct-to-chip cooling? It not only optimizes energy efficiency but also contributes to reduced operational costs over time. As organizations seek sustainable practices in their operations, these advanced systems play a crucial role in achieving those goals.

Built-in vs. External Cooling Systems

When considering liquid cooling options for data centers, it's essential to evaluate built-in versus external cooling systems. Built-in systems integrate directly with server racks or other hardware components, offering a streamlined approach that maximizes space efficiency and minimizes installation complexity. On the other hand, external systems can be more flexible and scalable but may require additional infrastructure investments.

Direct-to-chip liquid cooling typically falls under built-in solutions due to its design philosophy aimed at optimizing component-level heat dissipation. However, understanding what is direct-to-chip liquid cooling for data centers involves recognizing how both built-in and external setups can complement each other depending on specific requirements and constraints within a facility's architecture.

Ultimately, choosing between built-in or external systems depends on factors such as existing infrastructure compatibility and future scalability needs—both of which play pivotal roles in determining the best fit for an organization's unique situation.

Key Players in the Liquid Cooling Market

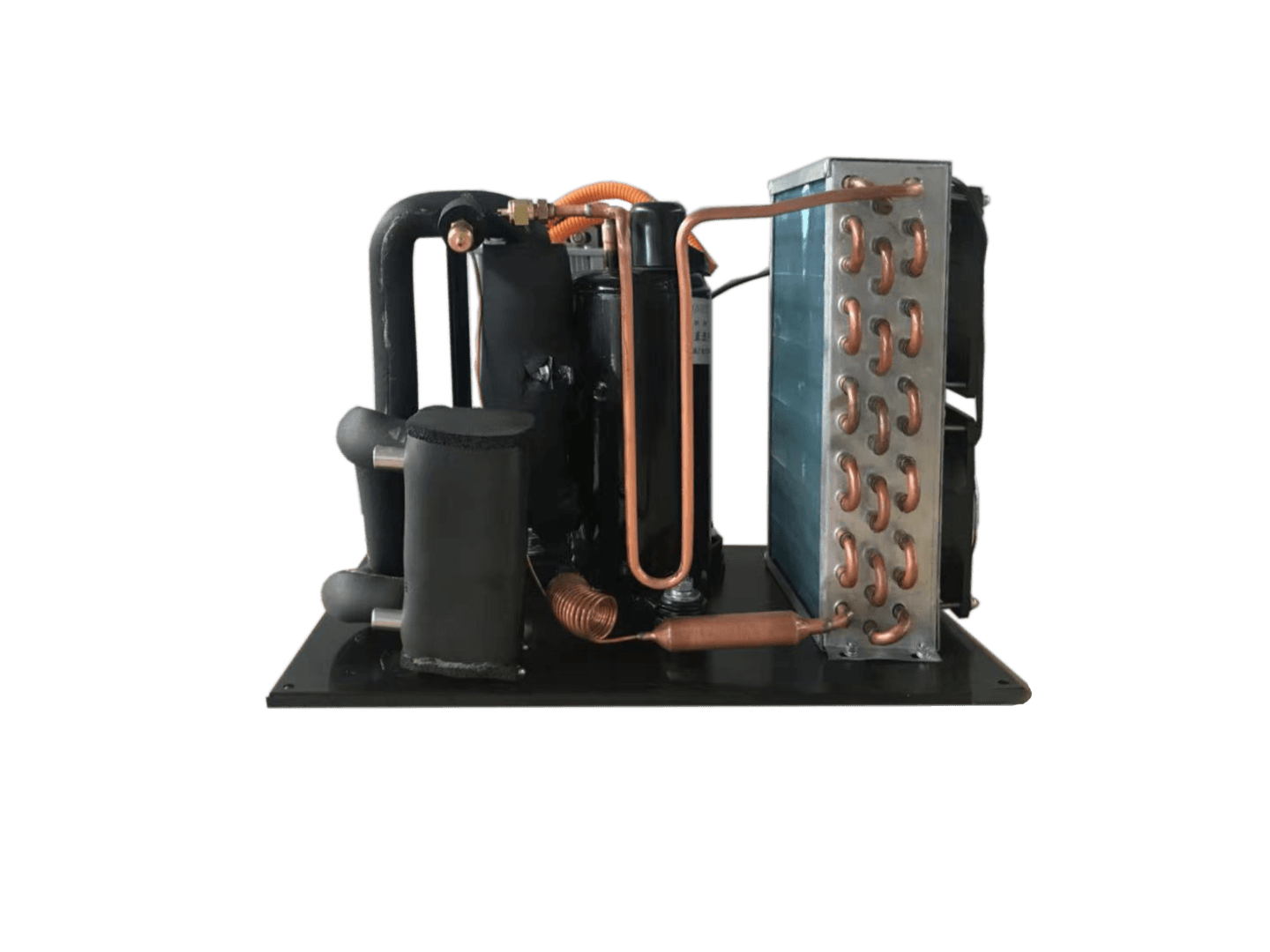

The landscape of liquid cooling options is populated by several key players who specialize in innovative technologies tailored to meet market demands effectively. Companies like Arctic Active Cooling have made significant strides with products such as their Coaxial Liquid Chiller—a sophisticated unit designed with high-efficiency refrigeration components that facilitate seamless integration into existing systems.

What is the difference between direct-to-chip and immersion cooling? While both methods offer substantial benefits over traditional air-cooling techniques, companies like Arctic Active Cooling focus on developing micro-cooling solutions that cater specifically to customers seeking modular integration capabilities within their machines or equipment setups.

In conclusion, understanding the various options available within the realm of liquid cooling helps organizations make informed decisions about what is best suited for their unique operational needs—especially when considering advancements like direct-to-chip technology that promise enhanced performance across data center environments.

Arctic Active Cooling’s Contribution

Arctic Active Cooling is at the forefront of revolutionizing data center efficiency through its innovative liquid cooling solutions. As organizations increasingly seek to optimize their thermal management systems, understanding what is direct-to-chip liquid cooling becomes essential. By integrating advanced technologies like the Coaxial Liquid Chiller, Arctic Active Cooling enhances the performance and reliability of data centers, making it a key player in the landscape of liquid cooling options for data centers.

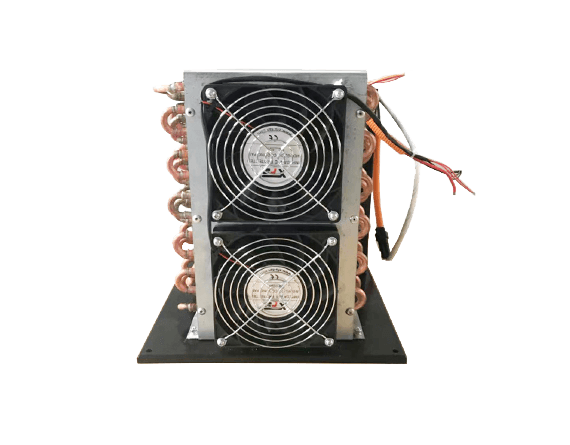

Overview of Coaxial Liquid Chiller

The Coaxial Liquid Chiller from Arctic Active Cooling is engineered with a high-efficient refrigeration mini compressor using refrigerants like R134a or R290. This compact unit features the smallest condenser and a coaxial tube evaporator, along with filter driers and drive boards—all seamlessly integrated into one sophisticated design. This setup not only simplifies installation but also delivers state-of-the-art micro cooling solutions that align perfectly with direct-to-chip liquid cooling requirements.

Integration with Existing Systems

One of the standout features of Arctic Active Cooling's offerings is how easily their systems can be integrated with existing setups. Customers looking to implement what is direct liquid cooling to chip can find that the Coaxial Liquid Chiller fits right into their current infrastructure without extensive modifications. The ability to connect their control board directly to our BLDC compressor driver board allows for optimized performance tailored specifically to each client's needs.

Customization for Optimized Performance

Customization plays a crucial role in maximizing efficiency when it comes to direct-to-chip liquid cooling systems. Arctic Active Cooling understands that every data center has unique requirements; thus, they offer tailored solutions that enhance thermal management while also improving energy efficiency and cost savings—key benefits of direct-to-chip cooling. By providing customizable options, clients can ensure that their systems not only meet but exceed operational expectations, paving the way for longer hardware longevity.

Conclusion

In the rapidly evolving landscape of data centers, the importance of efficient cooling solutions cannot be overstated. As we look towards the future, direct-to-chip liquid cooling stands out as a frontrunner in addressing the thermal challenges faced by high-performance computing systems. The adoption of this technology not only enhances operational efficiency but also aligns with sustainability goals, making it a pivotal element for modern data center designs.

The Future of Data Center Cooling

The future of data center cooling is undoubtedly leaning towards innovative solutions like direct-to-chip liquid cooling. As organizations strive to maximize performance while minimizing energy consumption, understanding what is direct liquid cooling to chip becomes essential. This method offers a targeted approach to thermal management that can significantly reduce energy costs and improve overall system reliability.

Embracing Direct Liquid Cooling Solutions

Embracing direct liquid cooling solutions means recognizing the myriad benefits they bring to data centers. What is direct-to-chip liquid cooling for data centers? It’s a sophisticated technique that ensures optimal temperatures for critical components, thereby extending hardware longevity and enhancing performance capabilities. With increasing demands on processing power, integrating these advanced systems will be key to maintaining competitive advantages in the tech industry.

Key Considerations for Implementation

When considering implementation, it's crucial to weigh various factors surrounding direct-to-chip versus immersion cooling options. What are the benefits of direct-to-chip cooling? These include superior thermal management and energy efficiency; however, site-specific needs must guide decisions on which method suits best for each scenario. Additionally, exploring available liquid cooling options for data centers will help organizations make informed choices tailored to their unique infrastructure requirements.