Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of logistics and storage, efficient warehouse cooling systems are not just a luxury; they're a necessity. With the right temperature control, businesses can protect their inventory, enhance employee comfort, and improve overall operational efficiency. So, what is the best cooling for a warehouse? It often boils down to understanding your specific needs and the available options.

Importance of Efficient Warehouse Cooling

Efficient warehouse cooling is crucial for maintaining product integrity and ensuring safety in working environments. Without proper temperature regulation, goods can spoil or degrade, leading to significant financial losses. Additionally, a well-cooled warehouse contributes to employee productivity—nobody wants to work in a sweltering space!

Key Features of Effective Cooling Systems

When considering how do you cool down a warehouse effectively, it's essential to look for key features in cooling systems that meet your needs. Look for energy efficiency, low maintenance requirements, and adaptability to different layouts or sizes—these factors can make all the difference in performance. Moreover, understanding what are the three types of cooling systems—evaporative cooling systems for warehouses, industrial air conditioners for warehouses, and traditional HVAC units—can help you make an informed choice.

Overview of ARCTIC Cooling Solutions

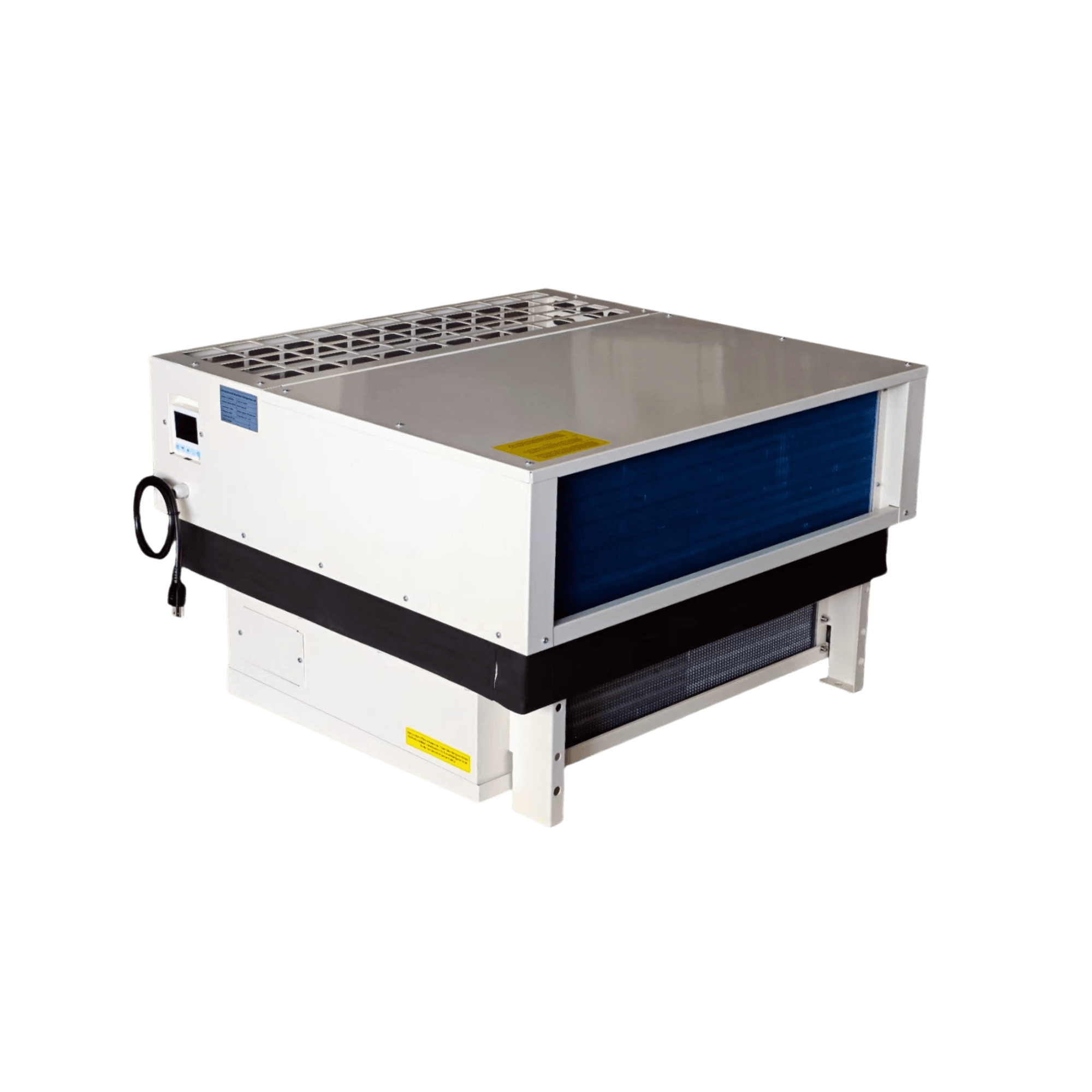

ARCTIC offers innovative solutions tailored specifically for modern warehouse environments. Their range includes advanced evaporative cooling systems designed for large spaces as well as robust industrial air conditioners that ensure optimal temperature control year-round. With ARCTIC's expertise in warehouse cooling systems, businesses can achieve peak efficiency while safeguarding their valuable assets.

Understanding Warehouse Cooling Systems

When it comes to maintaining an optimal environment for your products, understanding warehouse cooling systems is paramount. These systems ensure that your goods are stored at the right temperature, which can significantly impact their quality and longevity. So, let’s dive into the various types of cooling systems available and how they work to keep your warehouse cool.

Types of Cooling Systems Explained

What are the three types of cooling systems? In warehouses, we primarily see three main types: evaporative cooling systems for warehouses, industrial air conditioners for warehouses, and traditional refrigeration units. Evaporative cooling systems work by utilizing water evaporation to cool incoming air, making them energy-efficient and ideal for dry climates. On the other hand, industrial air conditioners provide a more controlled environment with precise temperature management but may consume more energy compared to evaporative options.

Traditional refrigeration units are often used in cold storage facilities where maintaining low temperatures is crucial. Each type has its own set of advantages depending on factors like climate conditions and specific storage requirements. Understanding these differences will help you determine what is the best cooling for a warehouse tailored to your needs.

How do you cool down a warehouse?

So how do you cool down a warehouse effectively? Start by assessing the size and layout of your space; this will inform your choice of cooling system. Utilizing large fans can help circulate air while also reducing humidity levels when combined with evaporative cooling systems for warehouses.

Implementing insulation strategies can also play a pivotal role in keeping heat out and cool air in—think reflective roofs or insulated doors! Finally, regular maintenance checks on your chosen system will ensure it operates at peak efficiency throughout the hot months.

Benefits of Proper Warehouse Cooling

Proper warehouse cooling offers several benefits that go beyond just keeping employees comfortable; it directly impacts product integrity as well! Maintaining optimal temperatures helps prevent spoilage or damage to sensitive goods such as food items or pharmaceuticals. Additionally, efficient warehouse cooling systems can lead to significant energy savings over time—especially when utilizing modern technologies like variable speed drives in industrial air conditioners.

Moreover, an adequately cooled environment contributes positively to employee productivity by creating a more pleasant working atmosphere. When employees feel comfortable, they’re more likely to perform better and contribute positively to overall operations within the facility.

What is the Best Cooling for a Warehouse?

When it comes to selecting the best cooling for a warehouse, one must consider several factors including size, layout, and specific storage needs. The right choice can significantly enhance operational efficiency while keeping products safe from heat damage. So, how do you cool down a warehouse effectively? Let’s explore some popular options.

Comparing Evaporative Cooling Systems for Warehouses

Evaporative cooling systems for warehouses are often hailed as an eco-friendly solution that can drastically reduce temperatures without breaking the bank. These systems work by pulling in warm air through moistened pads, allowing evaporation to cool the air before it circulates throughout the space. One of the key advantages of evaporative cooling systems is their energy efficiency; they consume less power compared to traditional air conditioning units while providing adequate cooling in dry climates.

However, it's essential to note that evaporative systems are most effective in low-humidity environments; they may not perform as well in areas with high moisture levels. Additionally, maintenance is crucial to ensure these systems function optimally—cleaning water pads and ensuring proper airflow can make all the difference in performance. Ultimately, when comparing warehouse cooling systems, evaporative options offer a cost-effective and environmentally friendly choice for many businesses.

Benefits of Industrial Air Conditioners for Warehouse

On the other hand, industrial air conditioners for warehouses provide robust and reliable cooling solutions regardless of external conditions. These units are designed to handle large volumes of space and maintain consistent temperatures throughout your facility—essential when storing temperature-sensitive products or materials. With advanced technology like variable refrigerant flow (VRF), these air conditioners can optimize energy use while delivering precise temperature control.

The primary benefit of industrial air conditioners lies in their versatility; they can be tailored to fit various warehouse layouts and operational needs without sacrificing performance. Furthermore, many modern units come equipped with smart technology that allows remote monitoring and adjustments—making it easier than ever to manage your warehouse cooling systems efficiently. In summary, while evaporative coolers have their perks, industrial air conditioners stand out for their reliability and adaptability across different environments.

Energy Efficiency Considerations

When evaluating what is the best cooling for a warehouse, energy efficiency should always be at the forefront of decision-making processes. Both evaporative cooling systems and industrial air conditioners offer unique advantages regarding energy consumption; however, understanding how each option impacts your utility bills is crucial for long-term savings. For example, evaporative coolers typically require less electricity but may need more water depending on usage—while industrial units might consume more power initially but provide better overall climate control.

Moreover, implementing energy-efficient practices such as regular maintenance checks can significantly extend equipment lifespan and enhance performance across all types of warehouse cooling systems. This proactive approach not only saves money but also promotes sustainability within your operations—a win-win situation! Therefore, whether you opt for an evaporative system or an industrial unit, ensuring optimal energy efficiency will pay off over time.

Installing the Right Cooling System

When it comes to installing the right cooling system, understanding your specific needs is crucial. Warehouse cooling systems are not one-size-fits-all; various factors such as size, layout, and inventory type will dictate the most effective solution. Whether you’re pondering what is the best cooling for a warehouse or trying to figure out how to AC a warehouse efficiently, a well-thought-out installation plan can make all the difference.

How to AC a warehouse effectively

Effectively cooling down a warehouse requires strategic planning and implementation of suitable solutions. Start by assessing your space and determining which type of cooling system aligns best with your operational needs—be it industrial air conditioners for warehouses or evaporative cooling systems for warehouses. Once you have chosen the right system, ensure that it is appropriately sized; an undersized unit will struggle to maintain cool temperatures, while an oversized one may lead to inefficiencies and higher energy costs.

Moreover, it's essential to consider airflow patterns within your warehouse when installing your cooling system. Proper airflow ensures that cool air circulates efficiently throughout the space, preventing hot spots that can compromise product integrity and employee comfort. By integrating zoning controls or strategically placing fans alongside your chosen cooling solution, you can enhance overall efficiency and effectiveness.

Planning for Space and Layout

Planning for space and layout is an often-overlooked aspect of installing warehouse cooling systems but is vital for optimal performance. Begin by mapping out your storage areas, workstations, and any machinery that generates heat; this information will inform where to install ducts or vents most effectively. Additionally, consider any physical barriers in your layout that could obstruct airflow—removing these obstacles can significantly improve how do you cool down a warehouse.

Another critical factor in planning is considering seasonal changes in temperature and humidity levels in your region; this knowledge helps determine whether you need more robust solutions like industrial air conditioners for warehouses or if evaporative cooling systems suffice during milder months. Ensure that there’s adequate space around each unit for maintenance access as well; cramped quarters can lead to increased downtime when repairs are needed.

Importance of Professional Installation

The importance of professional installation cannot be overstated when it comes to implementing effective warehouse cooling systems. While DIY might seem tempting as a cost-saving measure, improper installation can lead to inefficiencies that cost more over time than hiring trained professionals would have initially required. Experts understand what is the best cooling for a warehouse based on various factors such as layout, insulation quality, and expected heat loads from equipment or stored goods.

Furthermore, professional installers are familiar with local codes and regulations regarding HVAC installations—ensuring compliance avoids potential fines or future complications during inspections. They also bring valuable experience in troubleshooting common issues before they become significant problems; their insights into how do you cool down a warehouse effectively can save time and headaches later on.

Maintenance Tips for Warehouse Cooling

Maintaining your warehouse cooling systems is crucial for ensuring they operate at peak efficiency. Regular maintenance not only prolongs the life of your cooling solutions but also prevents costly breakdowns, which can disrupt operations. With a few simple routine checks and proactive measures, you can keep your warehouse cool and comfortable.

Routine Checks for Cooling Efficiency

To ensure that you're getting the most out of your cooling systems, it's essential to conduct routine checks for cooling efficiency. Start by inspecting filters in industrial air conditioners for warehouses; clean or replace them regularly to maintain airflow and efficiency. Additionally, check the thermostat settings and calibrate them if necessary—this helps avoid overworking the system and increases energy savings.

Another key aspect is to monitor the performance of evaporative cooling systems for warehouses, especially during peak usage times. Make it a habit to assess water levels and pump functionality regularly, as these factors significantly impact overall performance. Finally, don’t forget to inspect ductwork for any leaks or blockages that could hinder airflow throughout the warehouse.

Common Issues and Solutions

Even with diligent maintenance, issues can arise in warehouse cooling systems from time to time. One common problem is insufficient cooling, often due to dirty filters or blocked vents; addressing these quickly can restore optimal function. If you notice unusual noises coming from your industrial air conditioner for warehouses or evaporative systems, it may indicate mechanical wear—don’t hesitate to consult a professional.

Another frequent issue is inconsistent temperature distribution within the space; this could be a sign of improper layout planning when installing how to AC a warehouse effectively. Consider adjusting fan speeds or even repositioning certain units if hot spots persist in specific areas of your facility. Lastly, keep an eye on condensation buildup; excessive moisture can lead to mold growth and damage both products and equipment.

How to Extend the Lifespan of Cooling Systems

Extending the lifespan of your warehouse cooling systems requires proactive care and attention throughout their operational life cycle. Regularly scheduled professional inspections are vital—they help identify potential problems before they escalate into major repairs or replacements down the line. Additionally, investing in high-quality components during installation will pay off in longevity—after all, what is the best cooling for a warehouse if not one that's built to last?

Implementing energy-efficient practices also contributes significantly towards extending system longevity; this means monitoring usage patterns as well as optimizing settings based on seasonal changes in temperature demands. Don't overlook employee training either—ensuring staff understand how do you cool down a warehouse effectively can greatly reduce wear on equipment through proper use protocols. By combining these strategies with regular maintenance checks, you’ll create an environment where both people and equipment thrive.

Innovations in Warehouse Cooling Solutions

In the ever-evolving landscape of warehouse cooling systems, innovation is key to maintaining efficiency and sustainability. As businesses seek to optimize their operations, new technologies and methods are emerging that promise better performance and energy savings. This section will explore advances in evaporative cooling systems, custom solutions from ARCTIC, and future trends that are shaping the industry.

Advances in Evaporative Cooling Systems

Evaporative cooling systems for warehouses have seen significant advancements in recent years, enhancing their efficiency and effectiveness. These systems now utilize improved materials and designs that maximize evaporation rates while minimizing water consumption. By harnessing the natural process of evaporation, these innovative cooling solutions can significantly reduce indoor temperatures while being eco-friendly.

Moreover, modern evaporative cooling systems are designed with smart technology integration, allowing for real-time monitoring and adjustments based on environmental conditions. This means you can ask yourself: What is the best cooling for a warehouse? With these advanced systems, the answer is increasingly leaning towards evaporative methods due to their lower operational costs compared to traditional air conditioning units. As we continue to face climate challenges, these advancements will play a crucial role in sustainable warehouse management.

Custom Solutions from ARCTIC

When it comes to warehouse cooling systems, one size does not fit all—this is where ARCTIC shines with its bespoke solutions tailored specifically for your facility's needs. Understanding how do you cool down a warehouse effectively requires an analysis of various factors such as layout, product storage requirements, and local climate conditions. ARCTIC’s team of experts collaborates closely with clients to design customized cooling solutions that optimize airflow and temperature control.

These custom solutions often include a combination of industrial air conditioners for warehouses alongside innovative evaporative technologies tailored to specific environments or operational demands. By blending different approaches based on individual needs, ARCTIC ensures that each client receives a system that maximizes comfort while minimizing energy consumption—an essential aspect when considering how to AC a warehouse efficiently.

Future Trends in Warehouse Cooling Technology

Looking ahead, several exciting trends are poised to redefine warehouse cooling technology over the next few years. One major trend is the increasing use of automation and AI-driven analytics within warehouse cooling systems; this allows for predictive maintenance and optimized energy usage patterns based on real-time data analysis. As businesses become more data-driven, leveraging such technology will be crucial for maintaining peak efficiency.

Additionally, there’s a growing focus on integrating renewable energy sources into warehouse cooling strategies—think solar-powered air conditioning units or wind-assisted ventilation systems! These innovations not only contribute positively towards sustainability goals but also help answer the question: What are the three types of cooling systems? by expanding options beyond conventional methods into greener alternatives.

As we embrace these future trends in warehouse cooling technology with enthusiasm and foresight, companies like ARCTIC remain at the forefront of developing cutting-edge solutions that meet both current needs and future challenges.

Conclusion

In the world of logistics and storage, selecting the right warehouse cooling systems is crucial for maintaining product integrity and employee comfort. With various options available, it’s essential to assess your specific needs and consider factors like efficiency, cost, and scalability. Ultimately, understanding what is the best cooling for a warehouse can lead to significant long-term savings and operational success.

Selecting the Right System for Your Needs

When deciding how to AC a warehouse effectively, it's important to evaluate different types of cooling solutions tailored to your space. The three types of cooling systems—evaporative cooling systems for warehouses, industrial air conditioners for warehouses, and traditional air conditioning units—offer distinct advantages depending on your environment. Carefully analyzing these options will help you choose a system that not only meets your cooling requirements but also aligns with energy efficiency goals.

The Role of ARCTIC in Modern Cooling

ARCTIC has positioned itself as a leader in providing innovative warehouse cooling systems that cater specifically to modern logistical challenges. Their expertise in evaporative cooling systems for warehouses ensures businesses can achieve optimal temperatures while minimizing energy consumption. By partnering with ARCTIC, companies can take advantage of cutting-edge technology that enhances both performance and sustainability in their operations.

Ensuring Peak Efficiency in Warehouses

To ensure peak efficiency in warehouses, regular maintenance of your chosen cooling system is vital. Understanding how do you cool down a warehouse properly involves routine checks on equipment performance and addressing any common issues before they escalate into costly repairs. By implementing best practices in upkeep and leveraging advancements from manufacturers like ARCTIC, businesses can extend the lifespan of their industrial air conditioner for warehouse applications while maintaining an ideal working environment.