Introduction

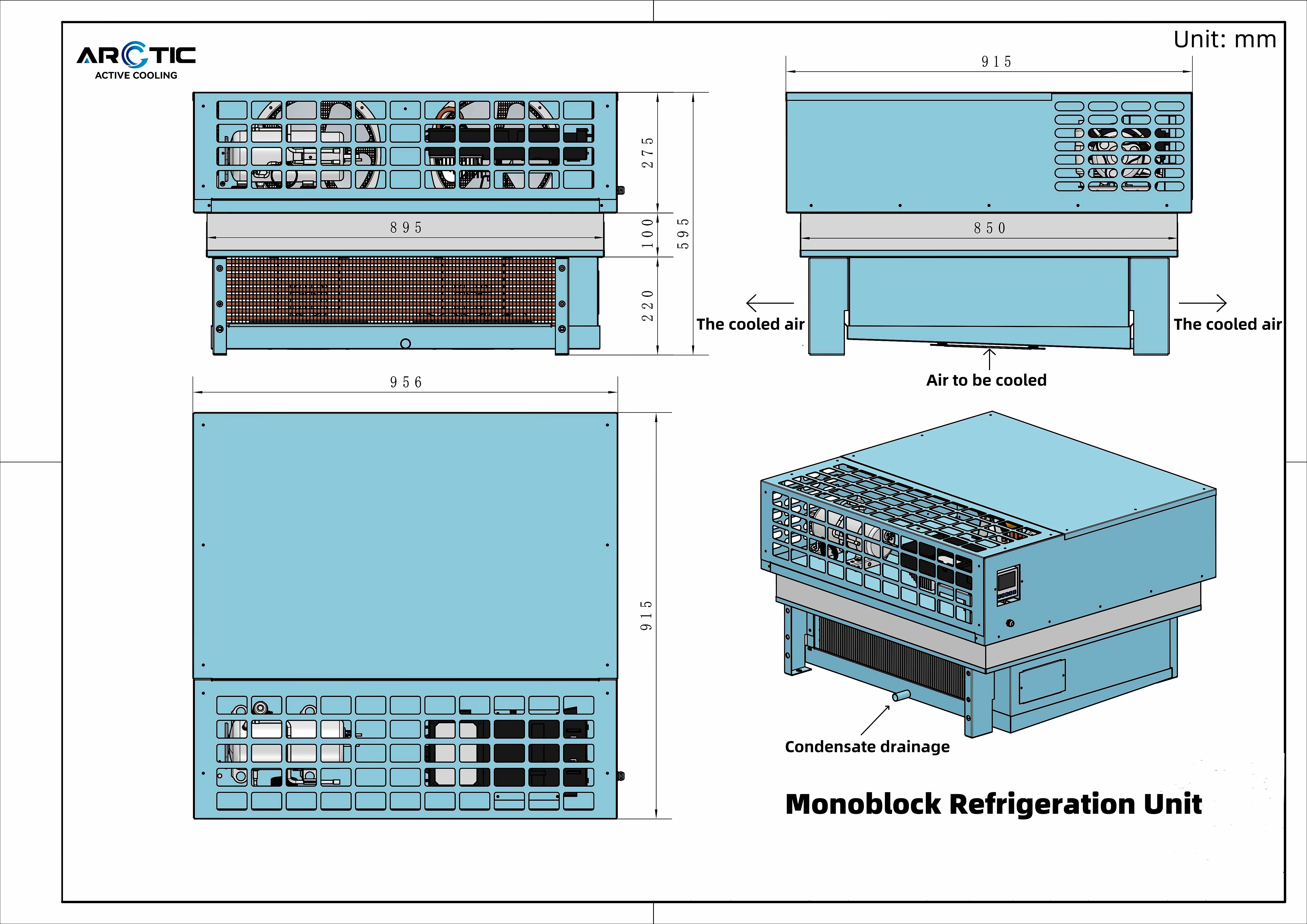

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of modern refrigeration, understanding the nuances of different compressor types is essential for making informed choices. The DC rotary compressor stands out as a key player in this arena, particularly with its integration of inverter technology. This combination not only enhances efficiency but also revolutionizes how we think about cooling systems.

Understanding DC Rotary Compressors

DC refrigeration compressors are designed to deliver superior performance by operating at variable speeds, unlike their traditional AC counterparts. But what is the difference between AC compressor and DC compressor? In essence, while AC compressors run at a fixed speed, DC compressors can adjust their output based on demand, leading to more tailored cooling solutions. This adaptability makes them particularly suitable for applications ranging from residential air conditioning to commercial refrigeration systems.

Benefits of Inverter Technology

The rise of inverter technology has transformed the landscape of air conditioning and refrigeration systems. Does an inverter AC have a DC compressor? Yes! Many modern inverter air conditioners incorporate DC compressors that allow for efficient temperature management and reduced energy consumption. By continuously adjusting the compressor's speed, these systems provide enhanced comfort levels while significantly lowering electricity bills—making them an attractive option for both homeowners and businesses alike.

The Role of ARCTIC in Innovation

When it comes to innovation in the realm of DC compressors for AC units, ARCTIC has carved out a niche with its cutting-edge designs and technologies. Their commitment to developing high-performance miniaturized compressors sets them apart from competitors and showcases their dedication to pushing boundaries in efficiency and reliability. As we explore further into this topic, it becomes clear that ARCTIC's advancements play a pivotal role in shaping the future landscape of refrigeration technology.

What is a DC Inverter Compressor?

In the world of cooling technology, understanding what a DC inverter compressor is can significantly enhance your knowledge of modern refrigeration systems. A DC refrigeration compressor utilizes direct current (DC) to power its operation, allowing for more efficient performance compared to traditional systems. This innovation is particularly beneficial in applications like air conditioning, where a DC compressor for AC can adapt its speed based on cooling demands.

Defining the DC Inverter Compressor

A DC inverter compressor is a type of compressor that adjusts its speed to provide precise temperature control and energy efficiency. Unlike conventional compressors that operate at fixed speeds, the inverter compressor modulates its output, thus optimizing energy use and reducing wear and tear on components. This flexibility makes it an ideal choice for various applications, especially when considering questions like What is the difference between AC compressor and DC compressor? The answer lies in their operational efficiency and adaptability.

Key Components of DC Refrigeration Compressors

Understanding the key components of a DC refrigeration compressor helps in grasping how these units achieve their impressive performance metrics. The main elements include the motor, which drives the compression process; sensors that monitor temperature and pressure; and electronic controls that adjust power input accordingly. Together, these components enable the inverter compressor to maintain optimal operating conditions while minimizing energy consumption.

How Does a DC Compressor Work?

How does a DC compressor work? Essentially, it employs advanced electronics to manage its motor speed based on real-time cooling requirements. By continuously adjusting its operation rather than cycling on and off like traditional units, it ensures consistent comfort levels while using less energy overall. This leads many to ask: Does an inverter AC have a DC compressor? The answer is yes—most modern inverter AC systems leverage this technology for improved efficiency.

Differences Between AC and DC Compressors

What is the Difference Between AC Compressor and DC Compressor?

At its core, the main difference lies in how each type of compressor operates. An AC compressor typically has a fixed speed; it either runs at full capacity or shuts down entirely when the desired temperature is reached. On the other hand, a DC refrigeration compressor can vary its speed, making it more adaptable to changing conditions—this adaptability is what makes a dc compressor for ac systems particularly appealing for modern applications. Additionally, while both types serve similar functions in air conditioning systems, they differ significantly in energy consumption patterns and operational efficiency.

A common question arises: Does an inverter AC have a DC compressor? The answer is yes; many inverter air conditioners utilize DC compressors due to their enhanced efficiency and quieter operation compared to traditional AC compressors. This technology not only ensures better comfort levels but also translates into lower energy bills for consumers over time. Ultimately, when considering which compressor is better for AC applications, it's clear that those equipped with inverter technology tend to outperform their traditional counterparts.

Energy Efficiency Comparisons

Energy efficiency remains one of the most significant considerations when comparing these two types of compressors. Generally speaking, dc refrigeration compressors are designed with efficiency in mind—thanks largely to their ability to modulate power usage based on real-time cooling requirements. This means that during mild weather conditions or when less cooling power is needed, a dc compressor can operate at lower speeds without wasting energy.

In contrast, traditional AC compressors run at full blast until set temperatures are achieved before shutting off completely—a process known as cycling—which can lead to increased electricity consumption over time. When evaluating energy efficiency comparisons between these two technologies, studies show that inverter compressors can save anywhere from 30% up to 50% more energy than standard models under similar conditions! This substantial difference highlights why many homeowners are making the switch toward more efficient solutions.

Application Scenarios for Each Type

Understanding application scenarios helps clarify where each type of compressor shines brightest. For instance, an AC compressor may be suitable for larger commercial spaces where consistent high-capacity cooling is required without much fluctuation in demand—think warehouses or factories where temperature control needs are stable throughout most days.

Conversely, dc compressors excel in residential settings or environments with varying thermal loads—like homes or offices where occupancy levels change frequently throughout the day (hello weekend get-togethers!). Not only do these systems provide superior comfort by adjusting their output according to real-time needs but they also contribute significantly towards reducing overall energy costs over time as well! So whether you're pondering about how does a DC compressor work or simply curious about which option fits best into your lifestyle's demands—the answer often leans toward embracing innovative technologies like inverter compressors.

Advantages of Using a DC Compressor for AC

In the realm of air conditioning, the adoption of a DC compressor for AC systems has transformed how we think about efficiency and comfort. Unlike traditional systems, these advanced compressors leverage inverter technology to provide a multitude of benefits that enhance both performance and user experience. Let's dive into the specific advantages that make DC refrigeration compressors stand out in today's market.

Benefits of Variable Speed Operation

One of the most significant advantages of using a DC compressor for AC applications is its ability to operate at variable speeds. Unlike conventional AC compressors that typically run at fixed speeds, an inverter compressor can adjust its output based on real-time cooling needs. This flexibility not only optimizes energy usage but also allows for smoother temperature regulation, making your indoor climate more enjoyable.

Variable speed operation means that the compressor can ramp up or down without turning on and off frequently, which is common in traditional systems. This results in less wear and tear on components, extending the lifespan of your unit while minimizing maintenance costs. So when considering What is the difference between AC compressor and DC compressor?, it’s clear that variable speed capability gives DC compressors a distinct edge.

Reduced Energy Consumption

Energy efficiency is another hallmark feature of DC refrigeration compressors compared to their traditional counterparts. The ability to modulate power consumption leads to significant reductions in energy use—often by as much as 30% or more! This means lower electricity bills for consumers and less strain on our planet's resources.

Moreover, many people wonder: Does an inverter AC have a DC compressor? The answer is yes! Most inverter air conditioning systems utilize these efficient compressors to achieve impressive energy savings while delivering optimal performance. By choosing a system with a DC compressor for AC applications, you're not just investing in comfort; you're also making an environmentally conscious choice.

Enhanced Comfort Levels

When it comes to comfort levels within your living space, nothing beats the performance delivered by a DC compressor for AC systems. These units provide consistent cooling without those annoying temperature fluctuations often associated with standard fixed-speed compressors. As they adjust their speed seamlessly, you’ll enjoy stable temperatures at all times.

Furthermore, due to their quieter operation—thanks to fewer start-stop cycles—DC refrigeration compressors contribute significantly less noise pollution compared to traditional models. So if you’re asking Which compressor is better for AC?, look no further than those equipped with inverter technology! In conclusion, opting for a system featuring a state-of-the-art inverter compressor not only enhances comfort but also offers long-term benefits in terms of efficiency and reliability.

ARCTIC's Approach to DC Compressors

ARCTIC has carved a niche for itself in the competitive landscape of refrigeration technology, particularly with its innovative approach to DC compressors. By focusing on miniaturization and efficiency, ARCTIC is setting new standards in the industry. The company's commitment to quality ensures that their inverter compressors not only meet but exceed consumer expectations.

Innovative Designs in Miniaturized Compressors

One of the standout features of ARCTIC's DC refrigeration compressor line is their innovative designs aimed at miniaturization. These compact units are engineered to fit into tight spaces without compromising performance, making them ideal for various applications. The question often arises: what is the difference between AC compressor and DC compressor? While AC compressors tend to be bulkier and less efficient, ARCTIC's miniaturized DC compressors provide a sleek alternative that maximizes both space and energy efficiency.

The design philosophy behind these miniature units allows for greater flexibility in installation, whether in residential or commercial settings. Furthermore, by utilizing advanced materials and engineering practices, ARCTIC has created a range of products that deliver superior performance while minimizing weight and size. This focus on innovation not only enhances user experience but also positions ARCTIC as a leader in the inverter compressor market.

Applications in Mobile Refrigeration

ARCTIC’s DC compressor for AC applications extends beyond conventional uses; they excel particularly well in mobile refrigeration systems. Whether it's for food trucks, recreational vehicles (RVs), or portable coolers, these compressors are designed to operate efficiently on varying power sources. Does an inverter AC have a DC compressor? Yes! Many modern inverter ACs utilize these advanced compressors to ensure optimal cooling performance even under fluctuating conditions.

The versatility of ARCTIC’s designs makes them suitable for environments where traditional air conditioning solutions might struggle due to power limitations or space constraints. This adaptability means users can enjoy reliable cooling wherever they go—an essential feature for those who rely on mobile refrigeration solutions. With an emphasis on energy savings and operational efficiency, it's clear why many consumers are choosing ARCTIC’s innovative products over traditional options.

Reliability and Sound Reduction Features

When considering which compressor is better for AC applications, reliability is paramount—and this is where ARCTIC shines with its advanced sound reduction features integrated into their DC compressors. These units are designed not only to perform efficiently but also to operate quietly, ensuring comfort without disruptive noise levels during use. How does a DC compressor work? By employing variable speed technology, these compressors adjust their output based on real-time cooling demands while maintaining low operational noise.

Moreover, ARCTIC prioritizes durability through rigorous testing processes that guarantee long-lasting performance under various conditions—be it high temperatures or constant usage cycles typical of mobile environments. This reliability translates into less frequent maintenance needs and greater peace of mind for consumers investing in high-performance cooling solutions like those offered by ARCTIC’s lineup of inverter compressors. With such features at play, it’s no wonder that customers consistently choose these models for both residential and commercial needs.

Conclusion

In the ever-evolving landscape of refrigeration technology, the choice of a compressor can significantly impact efficiency and performance. The DC inverter compressor stands out as a prime candidate for modern applications, particularly in air conditioning systems. With its ability to adjust speed and power consumption, it offers a level of flexibility that traditional AC compressors simply can't match.

Why Choose a DC Inverter Compressor?

When considering what is the difference between AC compressor and DC compressor, one must look at efficiency and adaptability. The inverter compressor operates at variable speeds, allowing it to modulate energy use based on current cooling needs, which leads to lower energy bills and enhanced comfort levels in your space. Additionally, many consumers are curious: does an inverter AC have a DC compressor? The answer is often yes; these systems leverage the benefits of DC technology to provide superior performance.

As you weigh your options for cooling solutions, it becomes clear that choosing a DC compressor for AC applications can lead to long-term savings and increased reliability. It’s not just about keeping cool; it's about doing so efficiently while minimizing environmental impact. With ongoing advancements in technology, investing in a DC refrigeration compressor is not just smart—it's essential for future-proofing your home or business.

The Future of Refrigeration Technology

The future looks bright for inverter compressors as innovation continues to drive improvements in energy efficiency and design capabilities. More manufacturers are adopting this technology, leading to better-performing units that consume less power while delivering optimal cooling performance. As we explore how does a DC compressor work within various applications—from residential air conditioning to commercial refrigeration—the potential benefits become increasingly apparent.

Moreover, advancements in smart technology mean that these compressors will likely integrate seamlessly with home automation systems. This integration allows users to monitor and control their cooling environments more effectively than ever before. As the world shifts toward sustainable practices, expect inverter compressors to play an integral role in shaping eco-friendly refrigeration solutions.

Final Thoughts on Efficiency and Performance

In conclusion, choosing between an AC or DC system boils down to understanding their respective strengths—especially concerning energy consumption and operational flexibility. Which compressor is better for AC? While both types have their merits, the evidence strongly favors the versatility offered by the DC refrigeration compressor when it comes to performance over time.

As consumers become more informed about their choices, those opting for inverter technology will likely reap significant rewards—both financially and environmentally—over traditional models. In this rapidly changing market landscape filled with possibilities for enhanced efficiency through innovative designs like those from ARCTIC or other leaders in the field, it's clear that embracing this new wave of refrigeration technology is not just wise but necessary.