Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of cooling technology, liquid cooling has become a popular choice for various applications, including PC water cooling and data center cooling. This innovative method utilizes a liquid coolant, such as water or a specialized fluid, to remove heat from a system, offering superior thermal performance compared to traditional air cooling methods.

Understanding Arctic Active Cooling

Arctic Active Cooling offers a range of micro-cooling systems that utilize liquid cooling technology to effectively manage heat in electric vehicle battery packs. These systems include the Coaxial Liquid Chiller, Plate Liquid Chiller, and DC Condensing Unit, providing efficient and reliable cooling solutions for demanding applications.

The Importance of Liquid Cooling

Liquid cooling is crucial in maintaining optimal operating temperatures for sensitive electronic components such as CPUs and GPUs in PCs. This method efficiently dissipates heat, ensuring high performance and longevity of these devices, making it an essential component for any high-performance computing system.

The Benefits of Liquid Cooling

The benefits of liquid cooling are numerous, including improved thermal efficiency, reduced noise levels compared to air coolers, and the ability to handle higher heat loads without compromising performance. In data centers, liquid cooling systems offer energy savings and enhanced reliability by effectively managing the heat generated by servers and other equipment.

What is Liquid Cooling?

Liquid cooling is a method of cooling that uses a liquid coolant, typically water, to remove heat from a system. In the context of Arctic Active Cooling, liquid cooling is utilized to efficiently cool electric vehicle battery packs and other compact spaces. This method offers superior heat dissipation compared to traditional air cooling systems.

How Arctic Active Cooling Utilizes Liquid Cooling

Arctic Active Cooling employs liquid cooling through its Coaxial and Plate Liquid Chillers, as well as its DC Condensing Unit for direct expansion systems. These systems use liquid coolant to actively remove heat from the surrounding environment, providing efficient and effective cooling solutions for various applications including electric vehicle battery packs.

Liquid cooling is a highly efficient method of removing heat from electronic components and other systems. By using liquid coolant, Arctic Active Cooling's Coaxial and Plate Liquid Chillers, as well as its DC Condensing Unit, are able to actively dissipate heat from the surrounding environment, ensuring optimal performance and longevity of the equipment. This innovative approach to cooling not only provides superior thermal management but also contributes to energy savings and environmental sustainability.

The Science Behind Liquid Cooling

Liquid cooling works on the principle of thermodynamics, where the liquid coolant absorbs heat from the system it is intended to cool and then dissipates that heat elsewhere. This process allows for more precise temperature control and greater thermal efficiency compared to air cooling methods.

Comparing Liquid Cooling to Air Cooling

In comparison to air cooling, liquid cooling offers several advantages such as higher thermal conductivity, lower operating temperatures, and quieter operation. Additionally, liquid cooling allows for more compact designs and can effectively cool high-performance components such as CPUs in data centers or PCs.

Moreover, liquid cooling systems are more efficient at dissipating heat compared to air cooling, which can result in better overall system performance. The use of liquid coolant allows for precise temperature control, ensuring that components operate within their optimal temperature range. This level of control is especially important for overclocking enthusiasts who require stable and consistent cooling for their high-performance hardware.

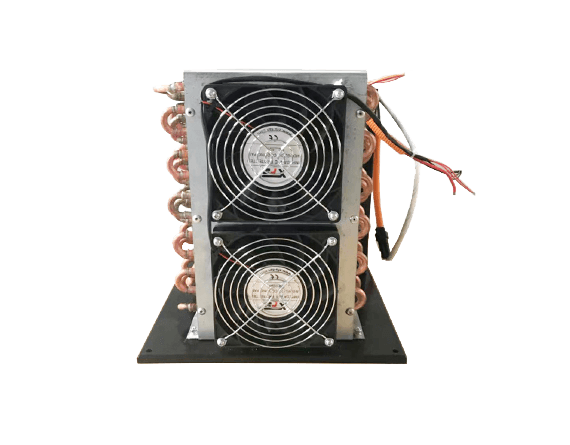

Arctic Active Cooling Micro DC Aircon

Arctic Active Cooling Micro DC Aircon is a cutting-edge cooling solution that offers a compact and efficient way to cool electric vehicle (EV) battery packs. This innovative system utilizes advanced liquid cooling technology to actively remove heat from the air, ensuring optimal performance and longevity of the battery pack. The Micro DC Aircon is designed to be lightweight and portable, making it an ideal solution for EV manufacturers looking to maximize space and weight efficiency in their vehicles.

Features and Capabilities

The Arctic Active Cooling Micro DC Aircon is equipped with state-of-the-art components that allow for precise temperature control and efficient heat dissipation. Its compact design makes it easy to integrate into tight spaces, while its high-performance capabilities ensure reliable cooling for EV battery packs. With its low power consumption and quiet operation, the Micro DC Aircon offers a sustainable and user-friendly cooling solution for electric vehicles.

Applications in Electric Vehicle Battery Cooling

The primary application of the Arctic Active Cooling Micro DC Aircon is in electric vehicle battery cooling. By actively removing heat from the battery pack, this system helps maintain optimal operating temperatures, prolonging the life of the batteries and ensuring consistent performance. Its compact size and efficient cooling capabilities make it an ideal choice for EV manufacturers looking to enhance the reliability and efficiency of their vehicles.

Advantages of Using Micro DC Aircon

One of the key advantages of using the Arctic Active Cooling Micro DC Aircon is its ability to provide effective cooling in a small and lightweight package. This makes it an excellent choice for electric vehicle manufacturers who prioritize space efficiency without compromising on performance. Additionally, its use of liquid cooling technology allows for more precise temperature control compared to traditional air cooling methods, ensuring optimal conditions for EV battery packs.

Coaxial Liquid Chiller and Plate Liquid Chiller

Exploring Different Liquid Cooling Methods

Liquid cooling is a method of heat removal that uses a coolant, such as water or a water-based solution, to transfer heat away from a component. In the case of PC water cooling, this involves using a series of tubes and radiators to circulate the coolant around the components, absorbing heat and then dissipating it through the radiator. In data centers, liquid cooling systems are used to remove heat from servers and other equipment, ensuring optimal performance and preventing overheating.

Benefits and Drawbacks of Coaxial vs Plate Liquid Chiller

When it comes to industrial applications, two common liquid chiller methods are coaxial and plate chillers. Coaxial chillers use a tube within a tube design to circulate the coolant, providing efficient heat transfer in a compact space. On the other hand, plate chillers utilize metal plates with channels for the coolant flow, offering flexibility in design but may require more space. While coaxial chillers are more space-efficient, plate chillers allow for greater customization.

In addition to their space efficiency, coaxial chillers also tend to have lower maintenance requirements compared to plate chillers. The tube within a tube design of coaxial chillers minimizes the risk of leaks and corrosion, reducing the need for frequent repairs or replacements. This can result in cost savings and less downtime for industrial operations. On the other hand, while plate chillers may require more space, they offer easier access for cleaning and maintenance due to their design, making them a practical choice for applications where regular upkeep is necessary.

Applications of Coaxial and Plate Liquid Chiller

Coaxial liquid chillers are often used in applications where space is limited or where efficient heat transfer is crucial. Their compact design makes them ideal for use in electric vehicle battery cooling systems where space is at a premium. Plate liquid chillers, on the other hand, are commonly employed in industrial settings where customization is necessary to accommodate specific cooling requirements. Both methods have their own set of advantages and are chosen based on the specific needs of the application.

Coaxial liquid chillers are also commonly used in HVAC systems for commercial and residential buildings. Their compact design allows for easy installation in tight spaces, making them an ideal choice for air conditioning units and refrigeration systems. Additionally, their efficient heat transfer capabilities ensure that the cooling process is effective, leading to lower energy consumption and cost savings for building owners.

DC Condensing Unit

DC condensing units utilize direct expansion systems to efficiently cool electric vehicle battery packs. By directly transferring refrigerant from the evaporator to the condenser, these systems effectively remove heat from the batteries, ensuring optimal performance and longevity.

Understanding Direct Expansion Systems

Direct expansion systems work by circulating refrigerant directly through the evaporator coils, absorbing heat from the surrounding air and converting it into a gas. The gas is then compressed and condensed back into a liquid form in the condenser, releasing the absorbed heat and allowing for efficient cooling of the battery packs.

Efficiency and Effectiveness in Cooling

Compared to other cooling methods, direct expansion systems offer high efficiency and effectiveness in cooling electric vehicle battery packs. The direct transfer of refrigerant allows for precise temperature control and rapid heat removal, contributing to improved battery performance and lifespan.

Direct expansion systems also offer the advantage of being more compact and lightweight compared to other cooling methods. This is particularly important for electric vehicles, where space and weight are at a premium. The reduced size and weight of the cooling system contribute to overall vehicle efficiency and performance, making direct expansion systems an ideal choice for electric vehicle battery packs.

Integration with Electric Vehicle Battery Packs

DC condensing units are specifically designed for seamless integration with electric vehicle battery packs. Their compact size and efficient cooling capabilities make them an ideal solution for maintaining optimal operating temperatures in electric vehicles, ensuring reliable performance and extended battery life.

DC condensing units are also designed to be highly customizable, allowing for seamless integration with a variety of electric vehicle battery pack configurations. This flexibility ensures that the cooling system can be tailored to the specific needs of different vehicle models, maximizing efficiency and performance. By offering a range of options for integration, manufacturers can optimize the design and layout of their battery packs without compromising on cooling capabilities.

The Future of Liquid Cooling

Advancements and Innovations in Liquid Cooling Technology

As technology continues to advance, liquid cooling systems are also evolving to become more efficient and effective. New materials and designs are being developed to enhance heat transfer and improve overall cooling performance. These innovations aim to make liquid cooling systems more compact, reliable, and cost-effective for a wide range of applications.

Potential Applications Beyond Electric Vehicle Cooling

While liquid cooling has been predominantly used for electric vehicle battery cooling, its potential applications extend beyond this specific use case. With advancements in technology, liquid cooling systems can be adapted for data centers, high-performance computing, and even personal computer (PC) water cooling. The versatility of liquid cooling makes it a viable solution for various industries seeking efficient thermal management.

Environmental Impact and Sustainability of Liquid Cooling

One of the key advantages of liquid cooling is its potential for environmental sustainability. By efficiently dissipating heat, liquid cooling systems can contribute to energy savings and reduced carbon emissions. Additionally, the use of environmentally friendly coolant solutions further enhances the sustainability aspect of liquid cooling technology.

Overall, the future of liquid cooling looks promising as it continues to evolve with technological advancements and find new applications across various industries.

Conclusion

In conclusion, when it comes to choosing the right cooling solution for your needs, it's important to consider the benefits of liquid cooling. With its ability to efficiently remove heat and provide effective cooling, liquid cooling offers a promising solution for various applications, including PC water cooling and data center cooling.

Choosing the Right Cooling Solution for Your Needs

When considering your cooling needs, it's essential to weigh the advantages of liquid cooling over traditional air cooling. Liquid cooling systems offer superior heat dissipation and can be tailored to specific requirements, making them an ideal choice for high-performance applications such as CPU and data center cooling.

Exploring the Potential of Liquid Cooling

The potential of liquid cooling extends beyond just PC water cooling - it has numerous applications in various industries. From electric vehicle battery packs to data centers, liquid cooling systems offer efficient and reliable solutions for managing heat loads and maintaining optimal operating temperatures.

Embracing Innovation in Cooling Technology

As we look towards the future, embracing innovation in cooling technology is crucial. Advancements in liquid cooling technology continue to push the boundaries of efficiency and sustainability, offering new opportunities for improved performance and environmental impact.

By understanding the benefits of liquid cooling and exploring its potential across different applications, we can make informed decisions about adopting innovative solutions that not only meet our current needs but also pave the way for future advancements in efficient and sustainable cooling technology.