Case Study

Enabling Ultra-Stable Analytical Instrument Performance with FPSC Stirling Cryocoolers.

Industry

* Analytical Instrumentation / Scientific Measurement

Application

* High-precision analytical instruments requiring cryogenic temperature control for sensors, detectors, and optics

Technology

* ARCTIC Cryo® Series Free-Piston Stirling Cryocoolers (FPSC)

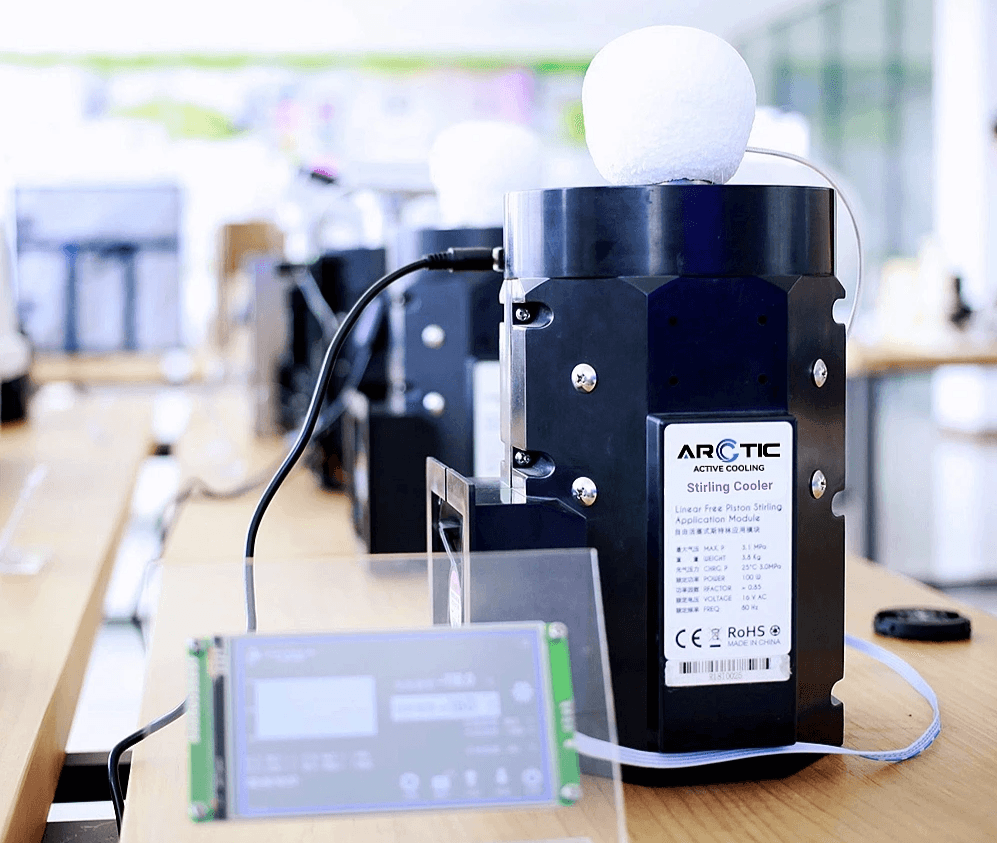

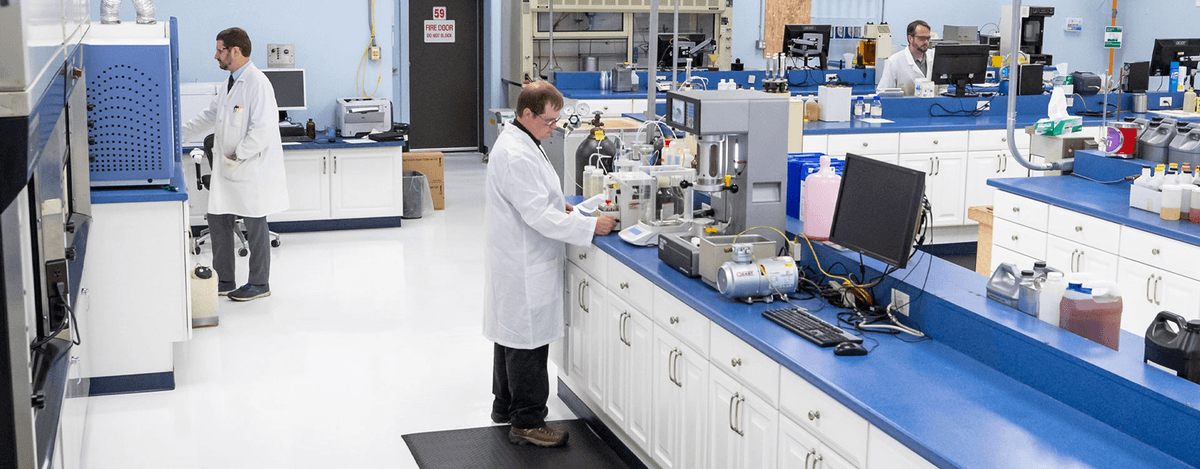

FPSC Stirling Ultra Cold Set-up

1. Background: Thermal Challenges in Modern Analytical Instruments

Analytical instruments play a critical role in scientific research, industrial quality control, pharmaceuticals, environmental monitoring, and advanced materials analysis. Techniques such as spectroscopy, chromatography, mass spectrometry, radiation detection, and optical sensing increasingly demand higher sensitivity, lower noise, and improved measurement stability.

As analytical performance requirements rise, thermal management becomes a limiting factor—particularly for instruments incorporating:

- Infrared (IR) and optical detectors

- CCD / CMOS imaging sensors

- Radiation and particle detectors

- Low-noise amplifiers (LNA)

- Superconducting or cryogenic sensor elements

Many of these components perform optimally only at cryogenic or sub-ambient temperatures, where thermal noise is minimized and signal-to-noise ratio (SNR) is maximized. Traditional cooling approaches—such as liquid nitrogen (LN₂), thermoelectric coolers (TEC), or bulky compressor-based refrigeration—present significant drawbacks in terms of operational cost, stability, maintenance, and system integration.

To overcome these limitations, a leading analytical instrument manufacturer partnered with ARCTIC to integrate FPSC Stirling cryocooler technology into its next-generation analytical platform.

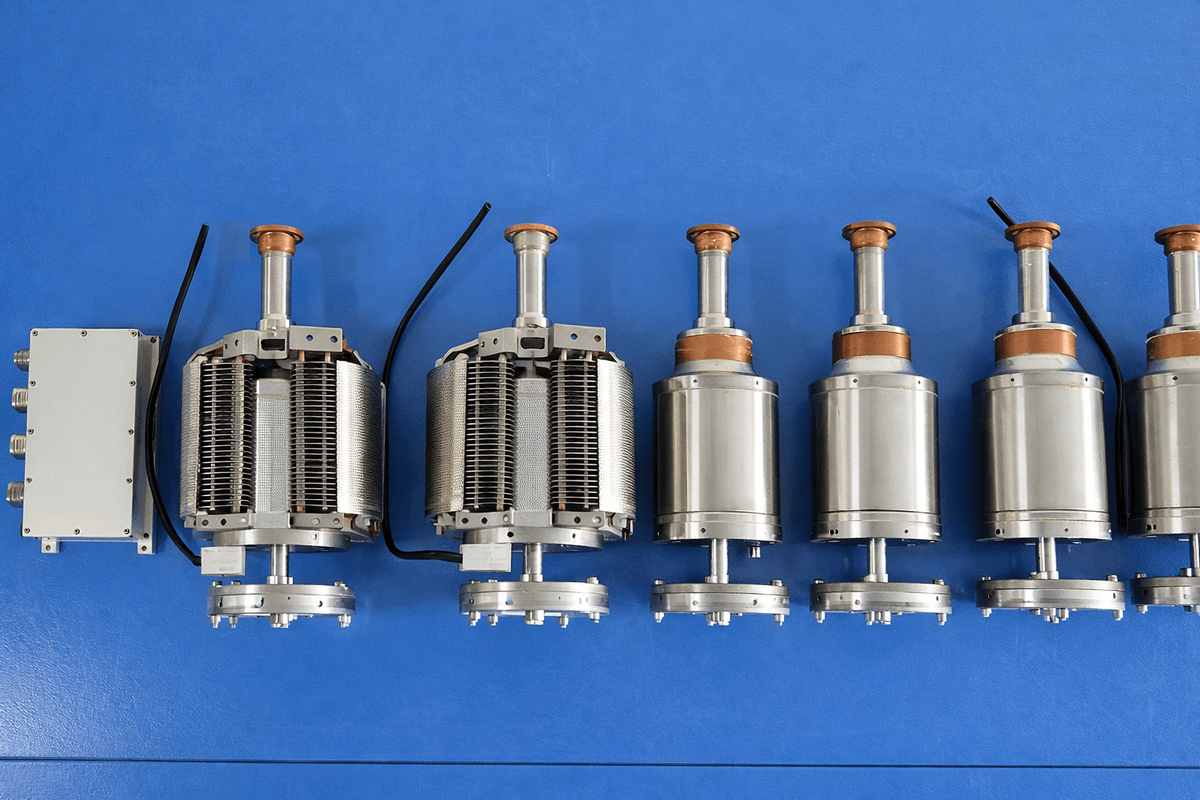

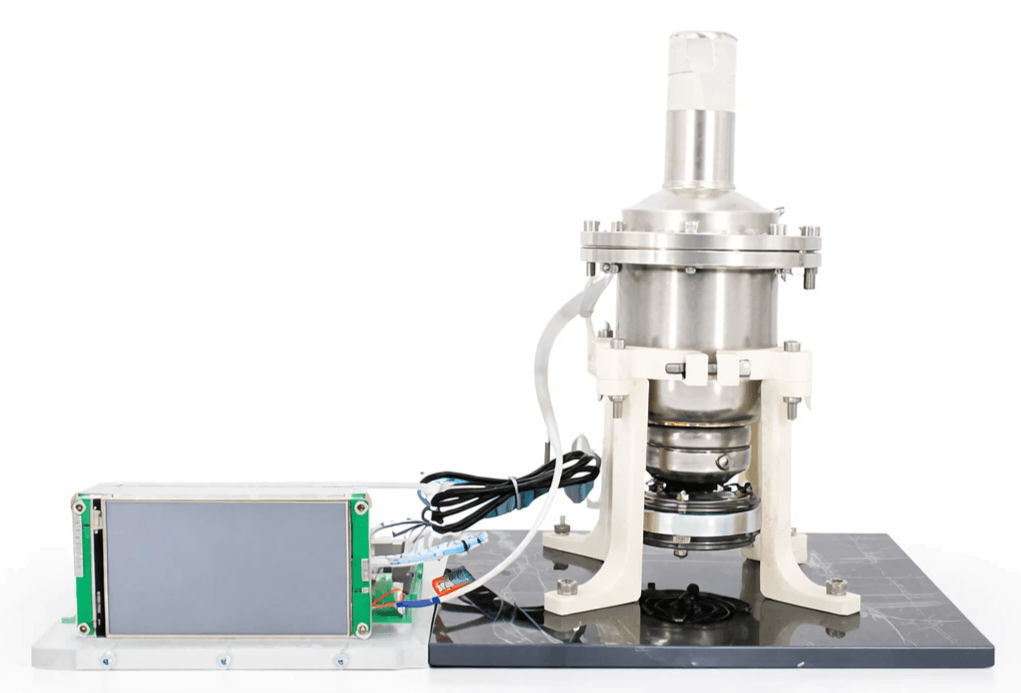

ARCTIC’s Cryo® FPSC Stirling cryocoolers

2. Customer Requirements and Design Objectives

The customer was developing a new family of high-end analytical instruments intended for continuous, long-duration operation in laboratory and industrial environments. Key performance and design requirements included:

Thermal Performance

- Operating temperature range: -86℃ to -160℃ (depending on detector type)

- Temperature stability: ±0.1℃ or better

- Fast cool-down time (< 30 minutes to operating temperature)

Mechanical and Acoustic Constraints

- Ultra-low vibration to avoid measurement distortion

- Quiet operation suitable for laboratory environments

- Compact form factor to fit within existing instrument housings

Reliability and Lifecycle

- Continuous 24/7 operation

- No routine maintenance

- Operational lifetime exceeding 50,000–80,000 hours

Commercial Considerations

- Lower total cost of ownership versus LN₂ cooling

- Scalable for volume production

- Compliance with environmental and safety regulations

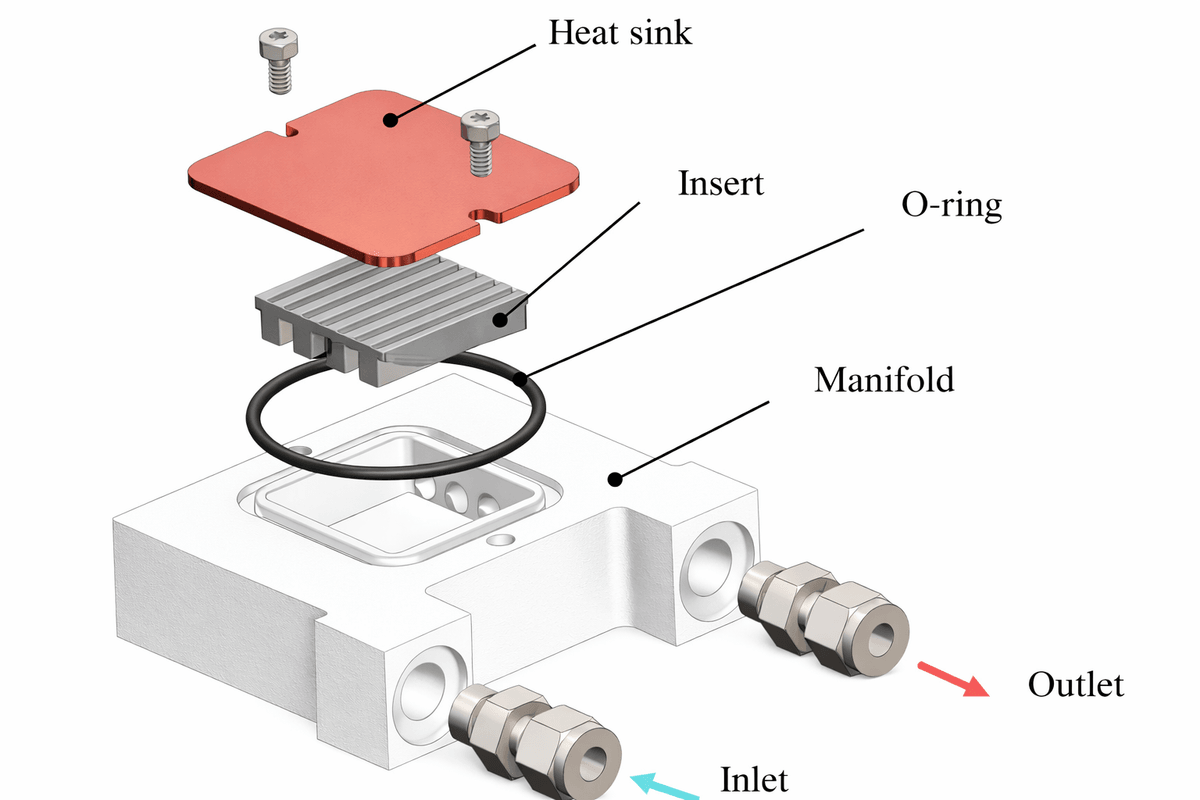

Stirling Cryocooler direct coolant to the heat sink for liquid-cooling of electronic components

FPSC Cryocooler for oil analysis instruments

3. Why ARCTIC FPSC Stirling Cryocoolers Were Selected

After evaluating multiple cooling technologies—including Gifford–McMahon (G-M) cryocoolers, pulse-tube cryocoolers, and TEC-based solutions—the customer selected ARCTIC’s Cryo® FPSC Stirling cryocoolers based on the following decisive advantages:

Proven Free-Piston Stirling Technology

ARCTIC’s FPSC cryocoolers are the result of over 10 years of continuous development and field-proven deployment. The free-piston architecture eliminates mechanical wear components such as crankshafts and bearings, resulting in exceptional reliability and longevity.

Compact, High Power Density

Compared to G-M systems, ARCTIC’s Stirling cryocoolers offer:

- Smaller footprint

- Lower mass

- Higher cooling power per unit volume

This made integration into space-constrained analytical instruments significantly easier.

Ultra-Low Vibration Design

Through precision balancing, flexure-bearing pistons, and optimized drive electronics, ARCTIC achieved extremely low vibration levels, protecting sensitive optical paths and detectors from microphonic noise.

Maintenance-Free Operation

Unlike LN₂ systems or oil-lubricated compressors, ARCTIC’s cryocoolers:

- Are completely oil-free

- Require no consumables

- Operate maintenance-free for years

Stirling Cryocooler for precise electronics and analysis instruments

4. System Architecture and Integration

Cooling Configuration

The analytical instrument integrates a ARCTIC Cryo® Stirling cryocooler directly with a cold finger assembly that interfaces with:

- Optical detector package

- Radiation sensor module

- Cryogenic pre-amplifier stage

A high-conductivity thermal interface ensures minimal thermal resistance between the cryocooler cold tip and the detector housing.

Temperature Control Loop

The system includes:

- Precision temperature sensors (Cernox / silicon diode)

- Closed-loop PID temperature control

- Digital interface to the instrument control system

This enables:

- Programmable setpoints

- Temperature ramp control

- Automated startup and shutdown sequences

5. Key Technical Parameters

Note: Values shown represent a typical analytical-instrument configuration using ARCTIC Cryo® FPSC models. Final parameters vary by model.

Cryocooler Performance

- Cooling capacity: 40W to 100W

- No-load temperature: < 40 K

- Operating temperature range: 0℃ to -160℃

- Cool-down time to 80 K: < 25 minutes

Mechanical & Electrical

- Input power: 40–100 W (model dependent)

- Drive voltage: DC 12V / 24 V or AC option

- Vibration level: < 0.1 g RMS (with isolation)

- Acoustic noise: < 40 dBA @ 1 m

Reliability

- Mean Time Between Failures (MTBF): > 50,000 hours

- Maintenance: None required

- Helium working gas: Sealed, lifetime charge

6. Performance Results and Validation

Noise Reduction and Measurement Stability

After integrating the ARCTIC Cryo® cryocooler, the customer observed:

- Up to 40% reduction in detector noise floor

- Significant improvement in signal-to-noise ratio

- Enhanced measurement repeatability

This directly translated into higher analytical accuracy and sensitivity, especially for low-concentration sample detection.

Thermal Stability

The closed-loop Stirling cooling system maintained:

- Temperature stability better than ±0.05 K over 24-hour operation

- Minimal thermal drift during extended measurement cycles

This eliminated the need for frequent recalibration common in LN₂-cooled systems.

Operational Efficiency

Compared with liquid nitrogen cooling:

- Zero consumables

- No operator intervention

- Lower operating cost over 5 years

- The system achieved full ROI in less than 24 months.

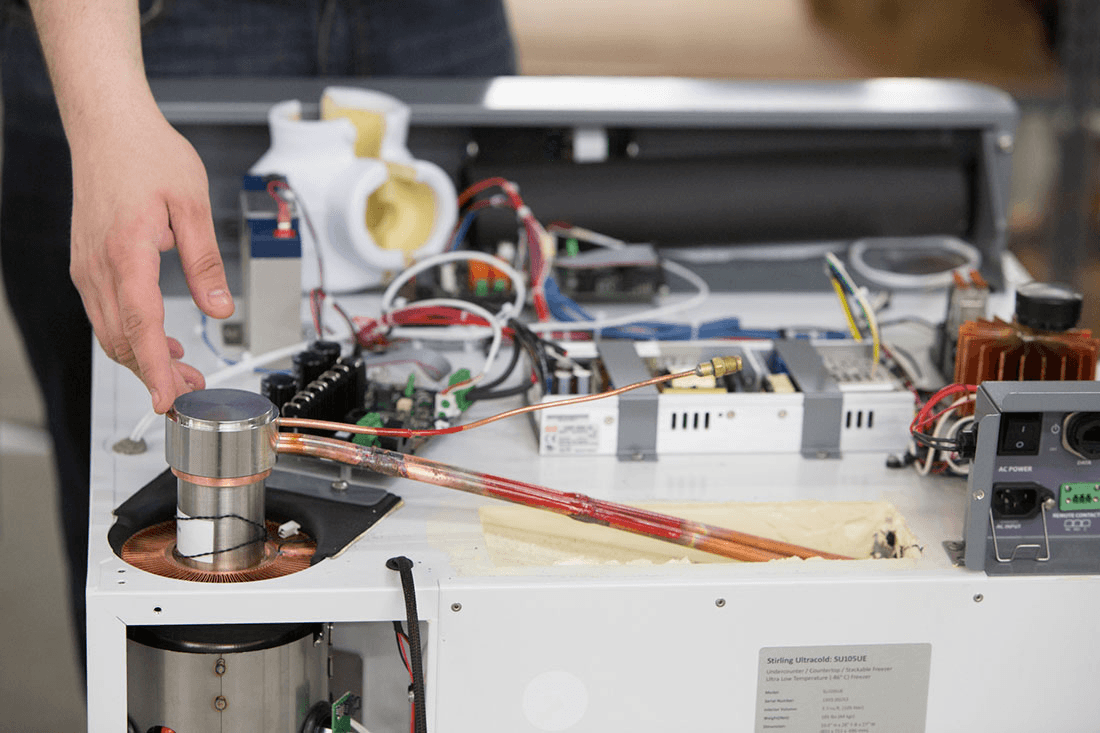

For education study set-up: Stirling cryocooler integrated into analytical instrument for cryogen-free detector cooling.

7. Advantages Over Competing Cooling Technologies

Versus Liquid Nitrogen (LN₂)

- No refilling logistics

- Improved safety

- Continuous unattended operation

Versus Thermoelectric Coolers (TEC)

- Much higher temperature lift

- Ability to reach true cryogenic temperatures

- Far higher cooling capacity at low temperatures

Versus G-M Cryocoolers

- Lower vibration

- Smaller and lighter

- Lower maintenance and operating cost

8. Environmental and Regulatory Benefits

ARCTIC FPSC cryocoolers are:

- Environmentally friendly

- Free of ozone-depleting substances

- Oil-free and leak-resistant

This simplifies compliance with:

- Laboratory safety standards

- Environmental regulations

- Cleanroom and pharmaceutical requirements

9. Impact on Product Commercialization

By adopting ARCTIC’s Stirling cryocooler technology, the customer was able to:

- Accelerate time-to-market

- Differentiate their instrument with cryogen-free operation

- Reduce total cost of ownership for end users

- Increase system uptime and customer satisfaction

The result was strong market adoption, particularly in pharmaceutical labs, research institutes, and industrial inspection facilities.

10. Long-Term Partnership and Customization

ARCTIC supported the customer beyond hardware supply by providing:

- Custom cold finger geometry

- Vibration isolation solutions

- Power electronics optimization

- System-level thermal simulations

This collaborative approach ensured optimal performance and seamless integration across multiple instrument models.

11. About ARCTIC FPSC Cryocooler

The successful deployment of ARCTIC Cryo® FPSC Stirling cryocoolers in advanced analytical instruments demonstrates the critical role of reliable, low-vibration, cryogenic cooling in modern measurement systems.

By combining high efficiency, exceptional reliability, compact design, and maintenance-free operation, ARCTIC’s Stirling cryocoolers enable analytical instrument manufacturers to push the boundaries of precision, sensitivity, and operational efficiency—without the complexity and cost of traditional cryogenic solutions.

As analytical technologies continue to evolve, ARCTIC remains a trusted partner in delivering next-generation cryogenic cooling solutions for science, industry, and innovation.