Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of maritime technology, ship battery cooling is an essential component that ensures the optimal performance and longevity of onboard power systems. With advancements in electric and hybrid vessels, understanding how does battery cooling work? becomes crucial for maintaining efficiency and safety. This introduction sets the stage for exploring various battery cooling options and their significance in modern marine applications.

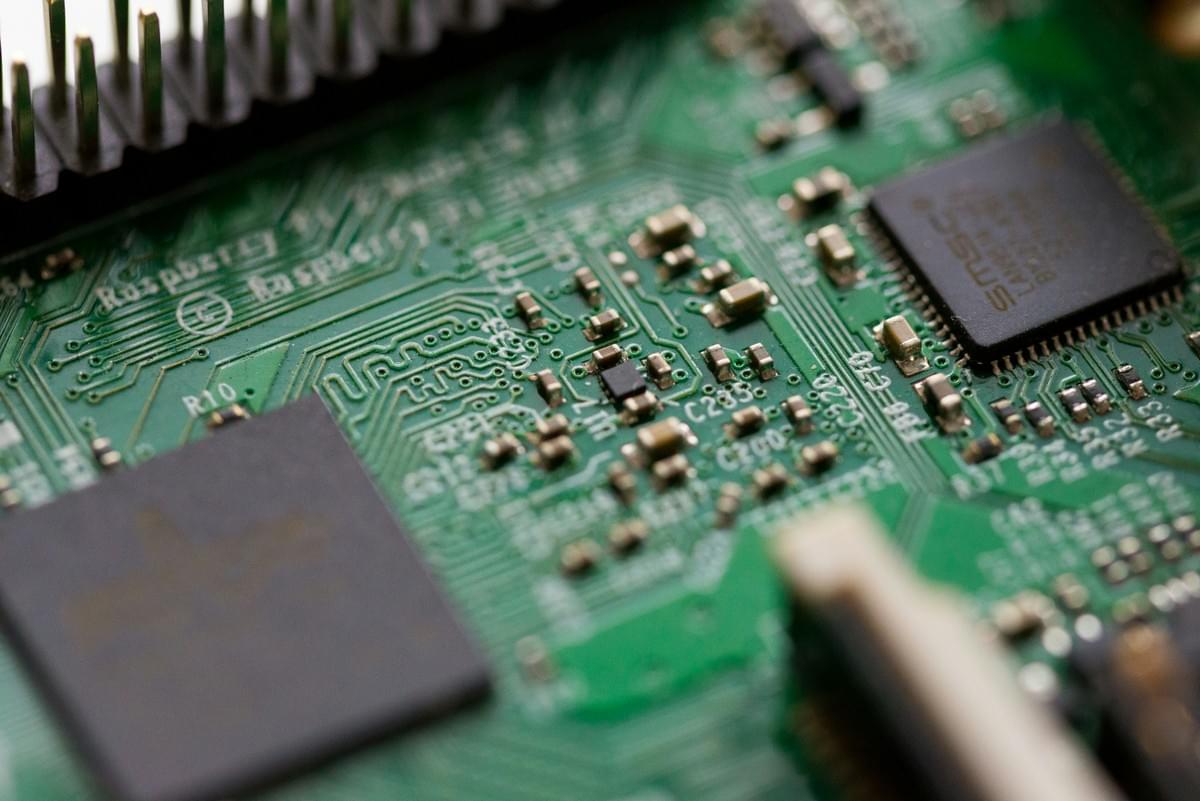

Understanding Ship Battery Cooling Systems

Ship battery cooling systems are designed to manage the heat generated by batteries during operation, particularly in electric and hybrid ships where energy storage is paramount. These systems aim to maintain batteries within a safe operating temperature range to ensure reliability and efficiency. By delving into how does battery cooling work?, we can appreciate the intricate mechanisms that keep these critical components functioning optimally.

The Importance of Efficient Cooling

Efficient cooling is vital for preventing overheating, which can lead to reduced performance, shorter lifespan, or even catastrophic failures in batteries. In a maritime context, where space is often at a premium, effective ship battery cooling solutions are not just beneficial but necessary for operational success. Understanding why efficient cooling matters helps highlight the risks associated with neglecting this crucial aspect of ship design.

Overview of Cooling Techniques

There are various techniques employed in ship battery cooling, each with its own advantages and challenges. From air-based methods that offer simplicity to liquid-cooling systems that provide superior thermal management, knowing what are the battery cooling options? allows vessel operators to make informed decisions based on their specific needs. As technology advances, emerging solutions continue to reshape our approach to managing heat in marine environments.

How Does Battery Cooling Work?

Understanding how battery cooling works is essential for optimizing performance and safety in maritime applications. Efficient ship battery cooling systems are crucial, as they prevent overheating, which can lead to reduced efficiency and potential hazards. This section will explore the fundamentals of heat transfer, the different cooling mechanisms available, and safety considerations regarding battery heat.

The Fundamentals of Heat Transfer

Heat transfer is the cornerstone of effective ship battery cooling. When batteries operate, they generate heat due to internal resistance and chemical reactions; thus, managing this heat is vital for maintaining optimal performance. The three primary modes of heat transfer—conduction, convection, and radiation—play a significant role in how energy dissipates from batteries during operation.

Conduction occurs when heat travels through solid materials connecting the battery cells to cooler surfaces or mediums. Convection involves the movement of fluids (air or liquid) that carry away heat from the battery surface into the surrounding environment. Radiation is less significant in this context but still contributes to overall thermal management by emitting infrared energy away from heated surfaces.

Cooling Mechanisms: Active vs Passive

When discussing how does battery cooling work?, it’s essential to differentiate between active and passive mechanisms. Active cooling systems utilize external power sources to enhance heat dissipation actively; these include fans or pumps circulating coolant around the batteries. In contrast, passive cooling relies on natural processes like airflow or thermal conduction without additional energy input.

Active systems are often more effective at rapidly reducing temperatures but may add complexity and weight to ship designs—something that could be a deal-breaker in tight spaces aboard vessels. On the other hand, passive cooling methods are simpler but may not provide sufficient temperature control under heavy loads or extreme conditions found at sea. Ultimately, choosing between these options depends on specific operational requirements and space constraints.

Safety Considerations for Battery Heat

Safety considerations for battery heat cannot be overstated when evaluating how does a ship engine cooling system work alongside ship battery cooling solutions. Overheating can lead to thermal runaway events in lithium batteries—a situation where rising temperatures cause further increases in temperature until combustion occurs. Therefore, implementing robust thermal management strategies is paramount for preventing such risks.

Proper monitoring systems must be installed alongside any chosen method of ship battery cooling to ensure real-time data on temperature fluctuations is available for operators onboard ships. Additionally, integrating fire suppression measures can mitigate risks associated with overheating batteries while enhancing overall safety protocols within maritime environments where lithium-ion technology is increasingly being adopted.

In summary, understanding how does battery cooling work? involves grasping fundamental principles such as heat transfer modes while weighing active versus passive techniques’ effectiveness against safety concerns related to high temperatures generated by lithium batteries used onboard ships today.

What Are the Battery Cooling Options?

When it comes to ship battery cooling, selecting the right cooling option is crucial for maintaining performance and longevity. The choice of cooling method can significantly impact efficiency and safety, especially in maritime applications where environmental conditions can vary dramatically. In this section, we'll explore the most common battery cooling options available today.

Air Cooling: The Popular Choice

Air cooling has emerged as a favored method for ship battery cooling due to its simplicity and cost-effectiveness. This technique involves circulating air around the batteries to dissipate heat, making it ideal for applications where weight and space are at a premium. Companies like Arctic have developed innovative solutions such as the Arctic Active Cooling Micro DC Aircon, which effectively removes heat from air circulating through electric vehicle battery packs.

While air cooling is straightforward to implement, it does come with limitations regarding efficiency at higher loads or during prolonged use. However, its low maintenance requirements make it an attractive choice for many ship operators looking to optimize their battery systems without breaking the bank. As we delve deeper into how does battery cooling work?, it's clear that air cooling remains a staple in various industries, including maritime.

Liquid Cooling: A Deeper Dive

Liquid cooling offers a more efficient alternative for ship battery cooling, particularly in high-capacity systems like those found on larger vessels or in demanding environments. This method utilizes liquid coolant circulated through channels or plates that directly contact the batteries, ensuring effective heat transfer away from critical components. Liquid-cooled modular Li-ion battery systems for ships have gained traction due to their ability to manage thermal loads more effectively than traditional air-cooled systems.

One significant advantage of liquid cooling is its capacity to maintain optimal operating temperatures even under heavy usage conditions, reducing risks associated with overheating. This technology allows for compact designs while accommodating high energy density batteries—an essential factor as shipping companies strive for greater efficiency and sustainability in their operations. As we consider what are the battery cooling options?, it's evident that liquid solutions are paving the way forward.

Emerging Technologies in Cooling

The landscape of ship battery cooling is evolving with emerging technologies that promise enhanced performance and efficiency. Innovations such as phase change materials (PCMs) and advanced thermal management systems are being explored to provide more effective temperature regulation without adding significant weight or complexity to existing systems. These technologies could revolutionize how we think about thermal management in maritime applications.

Moreover, integrating artificial intelligence into battery management systems could optimize how these emerging technologies operate by predicting thermal loads based on real-time data analytics—ensuring that batteries remain within safe operating temperatures at all times. As shipping continues to embrace electrification and sustainable practices, understanding how does a ship engine cooling system work? will become increasingly important alongside advancements in ship battery cooling methods.

How Does a Ship Engine Cooling System Work?

Understanding how a ship engine cooling system operates is crucial for optimizing performance and ensuring safety. These systems work to manage the heat generated by the engine, preventing overheating and maintaining efficient operation. Just as with ship battery cooling, effective thermal management is key to longevity and reliability in maritime applications.

Components of Engine Cooling Systems

A typical ship engine cooling system comprises several essential components, including heat exchangers, pumps, and cooling mediums like water or air. The heat exchanger allows for the transfer of heat from the engine to the coolant without mixing them directly. Additionally, pumps circulate the coolant through the system, ensuring that heat is effectively removed from critical areas of the engine.

In many cases, these systems integrate seamlessly with other cooling solutions on board, such as those used for ship battery cooling. By leveraging both active and passive cooling methods, ships can maintain optimal operating temperatures across various systems. This interconnectedness highlights how understanding How does battery cooling work? can inform better practices in managing overall vessel thermal dynamics.

Integration with Battery Cooling

The integration of ship engine cooling systems with battery cooling solutions is increasingly important as vessels adopt more advanced technologies like Liquid-Cooled Modular Li-ion Battery Systems for Ships. By aligning these two systems, ships can ensure that both engines and batteries operate within safe temperature ranges simultaneously. This synergy not only enhances performance but also reduces energy consumption by optimizing overall thermal management.

As electric propulsion becomes more common in maritime applications, exploring What are the battery cooling options? becomes essential for engineers looking to design efficient hybrid or fully electric vessels. The shared use of coolant fluids between engines and batteries can lead to significant space savings on board while improving overall efficiency through integrated designs. Ultimately, this means that understanding how these systems interact can lead to innovative solutions for modern shipping challenges.

Efficiency Gains from Proper Cooling

Properly managed ship engine cooling systems yield substantial efficiency gains across multiple fronts—fuel economy being one of them. When both engines and batteries are kept at optimal temperatures through effective thermal management strategies, it leads to reduced wear and tear on components over time. Furthermore, maintaining ideal operating conditions helps prevent costly downtime due to overheating or associated failures.

Incorporating advanced technologies such as Arctic Active Cooling micro-cooling systems into this mix can enhance performance even further by utilizing methods like air or liquid chilling effectively tailored for specific needs aboard vessels. These innovations provide a competitive edge in energy efficiency while ensuring compliance with environmental regulations—a win-win scenario! As we explore Do lithium batteries need cooling?, it's clear that effective integration between all onboard systems is vital for achieving peak operational efficiency.

Do Lithium Batteries Need Cooling?

When it comes to the longevity and performance of lithium batteries, effective cooling is not just a luxury—it's a necessity. The intricate dance of thermal management ensures that these powerhouses operate within safe temperature ranges, preventing performance degradation and extending their lifespan. Understanding how does battery cooling work? is essential for anyone involved in maritime applications, where reliable energy storage is critical.

Thermal Management of Lithium Batteries

Thermal management systems play a pivotal role in maintaining optimal operating temperatures for lithium batteries. These systems are designed to dissipate heat generated during charging and discharging cycles, ensuring that the battery operates efficiently without overheating. With various options available, including air cooling and liquid cooling, understanding what are the battery cooling options? can greatly influence the choice of system for ship battery cooling.

In maritime settings, where conditions can vary dramatically, an effective thermal management strategy helps prevent thermal runaway—a situation where increased temperature leads to further heating and potential failure of the battery system. By integrating advanced thermal management techniques into ship battery designs, operators can enhance both safety and efficiency while keeping maintenance costs at bay.

Risks of Overheating

Overheating poses significant risks to lithium batteries, potentially leading to reduced capacity or catastrophic failures like fires or explosions. When temperatures exceed recommended levels during operation or charging, chemical reactions within the cells can become unstable. This not only jeopardizes the safety of crew members but also threatens the integrity of vital systems on board.

In addition to safety concerns, overheating can severely impact performance metrics such as charge retention and cycle life—two factors critical for operational efficiency in marine environments. Therefore, understanding do lithium batteries need cooling? becomes paramount when designing systems intended for high-demand applications like those found on ships.

Best Practices for Lithium Battery Cooling

To mitigate risks associated with overheating in lithium batteries used on ships, implementing best practices in ship battery cooling is essential. Regular monitoring of temperature through integrated sensors allows operators to identify potential issues before they escalate into serious problems. Furthermore, utilizing advanced liquid-cooled modular Li-ion battery systems for ships offers enhanced heat dissipation capabilities over traditional air-cooling methods.

Employing a combination of active and passive cooling strategies enhances overall efficiency while reducing energy consumption from auxiliary systems designed solely for thermal regulation. In addition to robust design features that promote airflow or fluid circulation around cells, routine maintenance checks ensure that any obstructions are addressed promptly—keeping your ship's power source cool under pressure.

Liquid-Cooled Modular Li-ion Battery Systems for Ships

In the maritime world, liquid-cooled modular Li-ion battery systems are gaining traction as a reliable solution for ship battery cooling. These systems utilize liquid cooling technology to manage the thermal performance of batteries more effectively than traditional methods. As ships increasingly rely on electric propulsion and energy storage, understanding how battery cooling works becomes essential for optimizing performance and safety.

Advantages of Liquid Cooling in Maritime Applications

Liquid cooling offers several advantages over air cooling when it comes to ship battery cooling. First and foremost, it provides superior heat dissipation, allowing batteries to operate at optimal temperatures even under heavy load conditions. This efficiency not only prolongs the life of the batteries but also reduces the risk of overheating—a crucial factor when considering whether lithium batteries need cooling.

Moreover, liquid-cooled systems can be designed to fit snugly into tight spaces aboard ships, making them ideal for compact configurations. By integrating these systems with existing ship engine cooling systems, operators can achieve significant efficiency gains and maintain consistent thermal management across all onboard power sources. Ultimately, this synergy enhances overall vessel performance while ensuring that safety standards are upheld.

Case Studies of Successful Implementations

Several maritime companies have successfully implemented liquid-cooled modular Li-ion battery systems in their operations, showcasing the effectiveness of this technology in real-world applications. For instance, some ferries have adopted these systems to support hybrid propulsion setups that require robust energy storage solutions while navigating busy waterways. These implementations demonstrate not only how does a ship engine cooling system work but also highlight the seamless integration between engine and battery thermal management.

Another noteworthy case involves cargo vessels outfitted with advanced liquid-cooled battery packs designed specifically for long-haul journeys. These ships benefit from reduced weight and increased efficiency thanks to optimized heat management strategies that address overheating risks typically associated with lithium batteries. Such examples underscore the growing trend toward adopting innovative approaches in ship battery cooling technologies.

Future Trends in Battery Cooling Systems

Looking ahead, future trends in ship battery cooling are likely to focus on enhancing both efficiency and sustainability through advanced technologies and materials. Innovations such as phase change materials (PCMs) may emerge as viable solutions for passive thermal management alongside active liquid-cooling techniques—addressing concerns like do lithium batteries need cooling? more effectively than before.

In addition to material advancements, digital monitoring tools will play a pivotal role in optimizing thermal performance by providing real-time data on temperature fluctuations within the system. This ability will allow operators to proactively manage heat levels while maximizing operational efficiencies across various marine applications—ultimately paving the way for safer and more efficient vessels equipped with state-of-the-art ship battery cooling solutions.

Conclusion

In the world of ship battery cooling, understanding how various cooling techniques work is essential for optimizing performance and safety. Efficient cooling not only prolongs battery life but also enhances overall system reliability, making it a critical focus for maritime applications. By exploring different methods such as air and liquid cooling, we can appreciate the advancements available to manage heat effectively.

Key Takeaways on Cooling Techniques

When considering how does battery cooling work?, it's clear that both active and passive mechanisms play vital roles in maintaining optimal temperatures. Air cooling remains popular due to its simplicity, while liquid cooling offers superior efficiency for high-performance applications like ships. Ultimately, selecting the right method involves weighing factors such as cost, efficiency, and specific use cases.

The Role of Innovation in Battery Cooling

Innovation is driving the future of ship battery cooling systems with emerging technologies enhancing existing methods and introducing new solutions. For instance, Liquid-Cooled Modular Li-ion Battery Systems for Ships are gaining traction due to their effective thermal management capabilities. As we explore what are the battery cooling options?, it's evident that advancements like Arctic Active Cooling systems are setting new standards in performance and efficiency.

Final Thoughts on Ship Battery Optimization

In conclusion, do lithium batteries need cooling? Absolutely! Proper thermal management is crucial to prevent overheating and ensure safe operation aboard vessels. As we look ahead at future trends in battery technology and engine integration—like how does a ship engine cooling system work?—it’s clear that an efficient approach to ship battery optimization will be instrumental in shaping sustainable maritime operations.